When storms roll in and gutters overflow, the last thing any home or business owner wants is a flooded basement. A properly selected and maintained sump pump stands guard, pumping away water before it becomes a costly disaster. But not all pumps are created equal, and skipping annual testing can spell trouble when you need your pump most. In this guide, Ohio Plumbing and Boiler demystifies sump-pump types, explores battery-backup options, and explains why regular check-ups are non-negotiable for both residential plumbing and commercial plumbing applications. Ready to fortify your property against water woes? Dive in!

Choosing Your Champion: Pedestal vs. Submersible Sump Pumps

Selecting the right pump is step one in any plumbing maintenance plan. Here’s how the two main styles stack up:

Pedestal Pumps: Simplicity Above the Basin

- Design & Installation: The motor sits above the sump pit on a pedestal stand, with only the pump and float switch submerged.

- Advantages:

- Easier Access: Since the motor is outside the water, maintenance (like motor replacement) is straightforward.

- Lower Cost: Generally less expensive up-front than submersible units.

- Easier Access: Since the motor is outside the water, maintenance (like motor replacement) is straightforward.

- Drawbacks:

- Noisy Operation: Motor noise resonates above the pit.

- Less Efficient Water Removal: Larger footprint in pit limits discharge capacity in high-influx scenarios.

- Noisy Operation: Motor noise resonates above the pit.

Submersible Pumps: Power Where It Counts

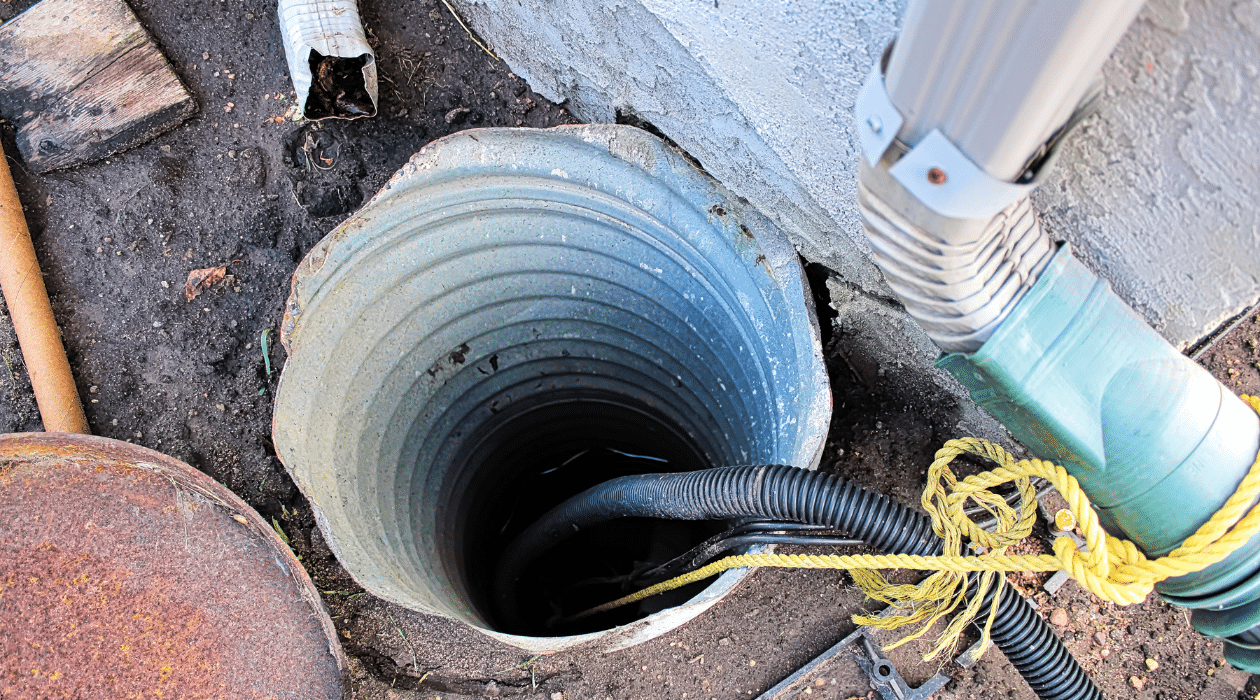

Design & Installation: The entire unit sits submerged inside the pit, with a sealed motor and pump in one assembly.

- Advantages:

- Quieter Performance: Water muffles motor noise.

- Higher Flow Rates: More compact design allows greater pumping capacity and faster water removal.

- Quieter Performance: Water muffles motor noise.

- Drawbacks:

- Maintenance Complexity: Servicing requires pulling the entire unit from the pit.

- Higher Initial Cost: Better performance and waterproofing come at a premium.

- Maintenance Complexity: Servicing requires pulling the entire unit from the pit.

For most Columbus homes and businesses, a submersible sump pump paired with a pedestal model as backup offers the best of both worlds: quiet, powerful primary pumping, plus straightforward emergency replacement if needed.

Battery-Backup Options: Preventing Dark-Hour Disasters

Power outages often coincide with severe storms, exactly when your sump pump is needed most. A battery-backup sump pump steps in when the lights go out:

- Dedicated Battery Systems:

- Stand-Alone Backup Pump: A smaller secondary pump, wired to a deep-cycle battery, activates when main power fails.

- Advantages: Uninterrupted protection, even during extended outages.

- Stand-Alone Backup Pump: A smaller secondary pump, wired to a deep-cycle battery, activates when main power fails.

- Integrated UPS-Style Backup:

- Uninterruptible Power Supply (UPS): Houses both the main pump and battery in a single enclosure.

- Advantages: Compact footprint; automatic switchover to battery power.

- Uninterruptible Power Supply (UPS): Houses both the main pump and battery in a single enclosure.

Sizing Your Backup: To calculate battery capacity, estimate your primary pump’s current draw and desired runtime, two hours of backup at 5 amps requires a 100-Ah battery. Always choose marine-grade or AGM batteries for reliable deep-cycle performance.

Annual Testing: Your Rainy-Season Ritual

Even the best pump can fail if left untested. Follow these annual testing steps to ensure peak performance:

- Visual Inspection:

- Check for debris, corrosion, or rust on the pump housing, inlet screen, and discharge piping.

- Check for debris, corrosion, or rust on the pump housing, inlet screen, and discharge piping.

- Float Switch Operation:

- Pour water into the pit; ensure the switch lifts freely and activates the pump at the correct water level.

- Pour water into the pit; ensure the switch lifts freely and activates the pump at the correct water level.

- Pump Activation & Discharge:

- Confirm water is rapidly expelled through the discharge line and that check valves prevent backflow.

- Confirm water is rapidly expelled through the discharge line and that check valves prevent backflow.

- Battery-Backup Verification:

- Simulate a power outage by unplugging the main pump. Observe the backup pump’s automatic engagement and battery performance.

- Simulate a power outage by unplugging the main pump. Observe the backup pump’s automatic engagement and battery performance.

- Voltage & Amp Draw Measurement (Commercial Only):

- Use a multimeter and clamp amp meter to compare running currents and voltages against manufacturer specs, deviations indicate motor or electrical issues.

- Use a multimeter and clamp amp meter to compare running currents and voltages against manufacturer specs, deviations indicate motor or electrical issues.

Document each test in a plumbing maintenance log, noting date, findings, and any corrective actions. This record is invaluable for troubleshooting and proves critical compliance for commercial plumbing inspections.

Maintenance Tips & Best Practices

Beyond annual testing, incorporate these plumbing maintenance habits:

- Quarterly Pit Cleaning: Remove mud, silt, and sediment that can clog pumps and switches.

- Discharge Line Inspection:

- Check for kinks, ice blockages (in winter), and frozen or broken check valves.

- Check for kinks, ice blockages (in winter), and frozen or broken check valves.

- Motor Lubrication:

- Some pedestal pumps require periodic bearing lubrication, consult your owner’s manual.

- Some pedestal pumps require periodic bearing lubrication, consult your owner’s manual.

- Professional Service Agreements:

- Enroll in our sump pump sales & services plan to receive biannual tune-ups, priority emergency response, and discounted parts.

- Enroll in our sump pump sales & services plan to receive biannual tune-ups, priority emergency response, and discounted parts.

Regular attention prevents minor issues from escalating into basement-flooding nightmares or commercial downtime.

Recognizing Signs of Impending Failure

Be alert to these red flags demanding immediate attention:

- Unusual Noises: Grinding, rattling, or high-pitched squeals suggest bearing wear or obstructions.

- Slow or Erratic Cycling: Short-cycling (rapid on/off cycles) indicates float switch misalignment or a worn impeller.

- Persistent Moisture in Pit: Continuous seepage may overwhelm pump capacity, consider upgrading to a higher-flow model.

- Corrosion & Rust Stains: Metal degradation around the pump base signals impending structural failure.

At the first hint of trouble, reach out, delaying repairs can cost thousands in water damage or lost business.

Upgrading for Commercial Resilience

Commercial plumbing environments, restaurants, office buildings, retail spaces, demand robust, high-capacity sump pump solutions:

- High-Volume Dewatering Pumps: Rate of 2,000–3,000 GPH (gallons per hour) to handle large basements or multiple floor drains.

- Redundant Pump Arrays: Dual submersible pumps wired in parallel, each capable of full load, ensure continuous operation if one pump fails.

- Smart Controls & Alarms: Integrate float-switch controllers with digital interfaces that send SMS alerts or trigger building alarms.

Tailoring your system to the application safeguards against unexpected flow spikes and upholds business continuity.

Expert Installation: Why Proper Setup Matters

A top-notch pump is only as good as its installation:

- Correct Pit Depth & Diameter: Ensures adequate sump volume and prevents short-cycling.

- Appropriate Discharge Routing: Piping should slope away from the foundation, with frost-proof design to endure Ohio winters.

- Check Valve Placement: Install just above the pump outlet to prevent backflow without air locks.

- Electrical Safety: Hardwired pumps require GFCI-protected circuits; battery backups need secure enclosures.

Our certified technicians adhere to local code and manufacturer guidelines, delivering reliable installations for both residential plumbing and commercial plumbing clients.

When to Call the Pros: Avoiding DIY Pitfalls

While homeowner maintenance is essential, certain tasks are best left to professionals:

- Major Pump Replacement: Upgrading from pedestal to submersible or increasing capacity requires expert sizing and electrical work.

- Complex Leak Diagnostics: Pinpointing refrigerant or hydraulic leaks around sealed motor housings demands specialized tools.

- Control System Integration: Installing smart alarms, automatic switchovers, or monitoring systems involves advanced programming and wiring.

For peace of mind, schedule annual inspections with Ohio Plumbing and Boiler, our team stands by Columbus businesses and homeowners for plumbing maintenance you can trust.

Conclusion: Safeguard Your Property with Proactive Pump Care

A well-chosen sump pump, paired with battery-backup options and annual testing, is your best defense against basement flooding and business interruptions. From understanding pedestal vs. submersible designs to executing thorough summer-time preparation, these steps protect both residential sanctuaries and commercial operations.

Reach out to us: Have questions or need service? Call 614-863-6666 or visit our website. At Ohio Plumbing and Boiler, we deliver expert sump-pump repairs, installations, and maintenance, keeping Columbus properties dry, safe, and stress-free.