Boost Efficiency: 5 Commercial AC Tune-Up Steps for Summer

Rising summer energy bills can erode commercial profit margins, but strategic AC tune-ups restore system efficiency and cut costs by up to 20–50 percent. Under the banner of 5 Must-Do Summer Commercial AC Tune-Up Steps for Energy Savings and Reliable Commercial AC Services, this guide demonstrates exactly why scheduled maintenance transforms energy consumption, extends equipment lifespan, and maintains comfortable, healthy indoor environments. You will discover: why tune-ups are essential for efficiency and reliability, the five critical service steps, key supplemental tasks to maximize performance, how service contracts ensure consistent maintenance, indicators for professional intervention, common problems prevented by tune-ups, and system-specific considerations for rooftop, split, and VRF installations. Integrating these practices with expert commercial AC services delivers predictable savings and dependable cooling throughout the hottest months.

Why Are Commercial AC Tune-Ups Essential for Energy Savings and System Reliability?

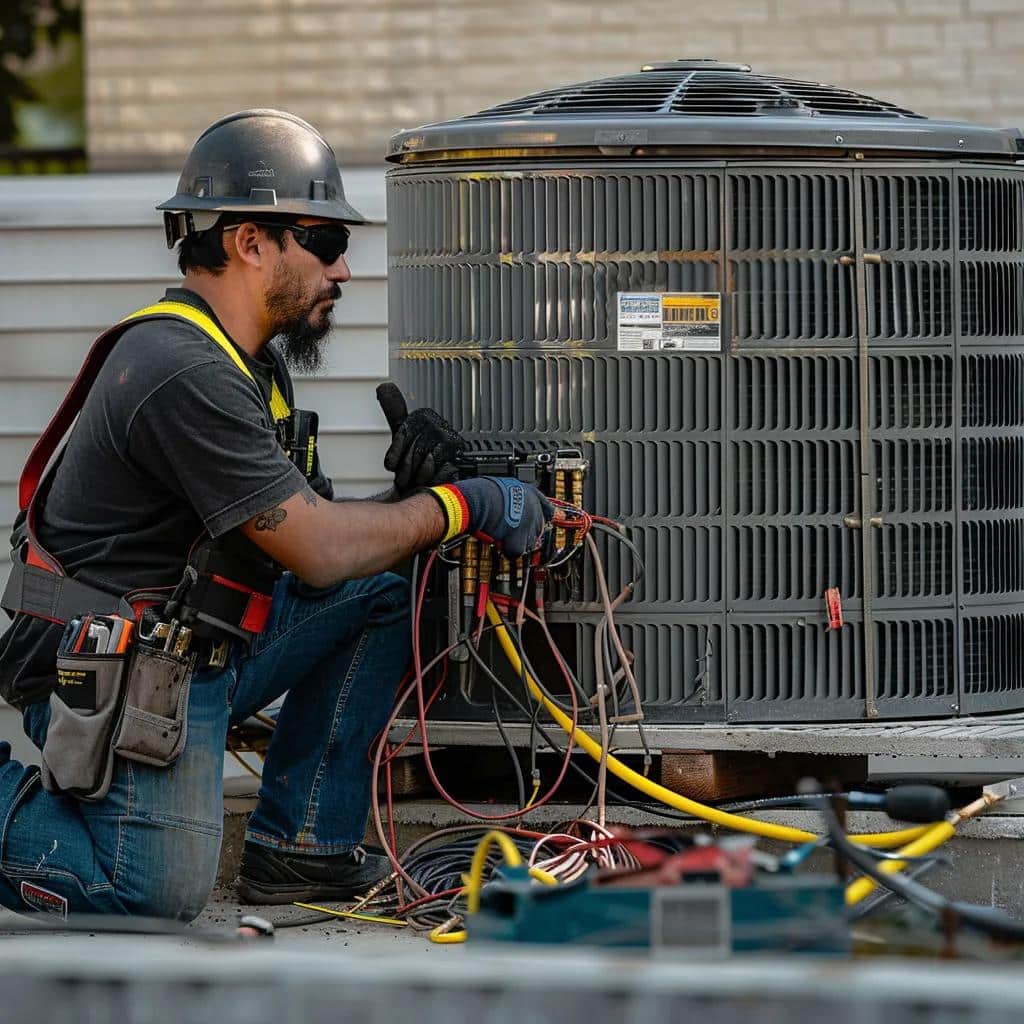

A commercial AC tune-up is a proactive maintenance process that inspects, cleans, and calibrates every component of the cooling system to ensure peak performance. By systematically addressing friction points, airflow restrictions, refrigerant imbalances, and electrical issues, tune-ups reduce power draw and prevent costly failures. For example, a facility that implemented seasonal tune-ups saw its summer utility bills drop by 18 percent while avoiding a compressor replacement. Understanding these mechanisms highlights how routine servicing underpins both energy savings and operational continuity.

How Do Regular Tune-Ups Reduce Commercial AC Energy Consumption?

Regular tune-ups reduce energy consumption by ensuring each system component operates under optimal conditions.

- Clean Airflow Paths – Removing debris from filters and coils minimizes airflow resistance and reduces blower energy usage.

- Proper Refrigerant Charge – Correct refrigerant levels maintain full cooling capacity without overworking the compressor.

- Tight Electrical Connections – Securing wiring and terminals prevents voltage drops that increase motor amperage.

- Calibrated Controls – Accurate thermostat settings and sensor alignment eliminate excess runtime.

By restoring original design parameters, tune-ups lower kilowatt-hour demand and support sustained energy efficiency.

Energy Savings from AC Tune-Ups

Regular commercial AC tune-ups can significantly reduce energy consumption by optimizing system components. This includes cleaning airflow paths, ensuring proper refrigerant levels, securing electrical connections, and calibrating controls. These actions collectively lower energy demand and support sustained efficiency.

This research supports the article’s claims about the energy-saving benefits of regular AC maintenance.

What Are the Cost Savings and Lifespan Benefits of Preventative Commercial AC Maintenance?

Preventative maintenance delivers quantifiable ROI through reduced repair costs and extended equipment life.

- Facilities report saving $4–$9 in emergency repairs for every $1 spent on tune-ups.

- Routine servicing can lengthen a commercial AC unit’s lifespan by 30–50 percent.

- Early detection of worn parts avoids catastrophic failures and associated downtime expenses.

Benefits of Preventative Maintenance

Preventative maintenance delivers a return on investment through reduced repair costs and extended equipment life. Facilities often report substantial savings in emergency repairs for every dollar spent on tune-ups. Routine servicing can also extend the lifespan of a commercial AC unit.

This citation reinforces the economic advantages of proactive maintenance, as discussed in the article.

How Does Maintenance Improve Indoor Air Quality and Comfort in Commercial Buildings?

Routine tune-ups enhance indoor air quality (IAQ) by eliminating contaminants that compromise occupant health and productivity. Visit our indoor air quality services for more information.

- Filter Replacement removes dust, pollen, and microbial growth, reducing airborne particulates.

- Coil Cleaning prevents mold colonies on condenser and evaporator surfaces.

- Drain Line Clearing avoids water backups that foster bacteria.

Cleaner air contributes to a comfortable environment that supports employee well-being and sustained operations, linking energy efficiency with health outcomes.

How Do Tune-Ups Prevent Unexpected Commercial AC Breakdowns and Downtime?

Tune-ups avert unplanned system outages by identifying and addressing wear before it escalates.

- Component Wear Inspection spots aged belts, bearings, and motors that can fail under load.

- Leak Detection uncovers refrigerant or water leaks that degrade performance and damage equipment.

- Electrical Testing highlights unsafe voltages and failing capacitors.

By intervening early, tune-ups maintain continuous cooling, protecting business continuity during peak demand.

What Are the 5 Must-Do Summer Commercial AC Tune-Up Steps for Maximum Energy Savings?

Summer tune-ups focus on five core tasks that yield immediate efficiency gains and reliability improvements. These steps align with industry best practices for commercial AC services and drive both energy savings and system resilience.

Step 1 – How and When Should You Clean or Replace Commercial AC Air Filters?

Regular filter maintenance ensures unobstructed airflow and prevents excessive system strain. Change or clean filters every 1–3 months, depending on building occupancy and air quality. Look for these signs of a dirty filter:

- Visible dust accumulation on the surface

- Reduced airflow from supply vents

- Higher static pressure readings on the gauge

Replacing filters at recommended intervals restores balanced airflow and reduces blower motor runtime.

Step 2 – Why Is Inspecting and Cleaning Evaporator and Condenser Coils Critical for Efficiency?

Cleaning coils maintains efficient heat exchange and prevents energy waste. Evaporator coils draw heat from indoor air, while condenser coils reject heat outdoors; dirt on either surface compromises this process. A typical

is shown below:

| Coil Location | Recommended Cleaning Frequency | Impact of Cleaning |

|---|---|---|

| Evaporator Coil | Annually (or biannually) | Restores indoor heat absorption |

| Condenser Coil | Quarterly in dusty environments | Maximizes outdoor heat rejection |

Assessing and cleaning both coils removes buildup that can increase energy consumption by up to 25 percent.

Step 3 – How to Check Refrigerant Levels and Detect Leaks in Commercial AC Systems?

Adequate refrigerant charge is essential for full cooling capacity and compressor protection. Technicians measure pressure readings, compare them to manufacturer specifications, and use electronic detectors to locate leaks. Common leak indicators include:

- Frost formation on refrigeration lines

- Hissing sounds near fittings

- Declining cooling performance without changes in settings

Prompt leak repair and recharge preserve system integrity and efficiency.

Step 4 – What Electrical Connections and Components Should Be Inspected During Tune-Ups?

Electrical safety and component reliability are verified by tightening connections, testing capacitors, relays, fuses, and inspecting wiring insulation. Key checks include:

- Capacitor Capacitance to ensure proper motor start and run support

- Contactor Contacts for pitting or burn marks

- Circuit Breakers and Fuses for correct amperage ratings

- Wire Integrity to prevent arcing and voltage drops

These inspections mitigate fire hazards and ensure motors and controls operate within design parameters.

Step 5 – How to Calibrate Thermostats and Optimize Settings for Energy Management?

Accurate thermostat calibration aligns actual temperatures with setpoints, minimizing unnecessary compressor cycles. Use the following best practices:

- Program setback schedules for off-peak hours

- Validate sensor placement away from heat sources and direct sunlight

- Integrate networked controls for multi-zone coordination

Optimized settings deliver consistent comfort, reduce wear, and support automated energy management strategies.

What Additional Maintenance Tasks Enhance Commercial AC Performance Beyond the 5 Steps?

To achieve comprehensive system health, incorporate these supplemental tasks that reinforce efficiency and longevity.

Why Is Commercial AC Drain Line Cleaning Important for System Health?

Clogged drain lines cause condensate backups and water damage to equipment and building interiors. Cleaning the drain pan and flushing lines with a mild biocide prevents mold and structural issues, setting the stage for reliable moisture management.

How Does Inspecting Blower Motors and Fans Improve Airflow and Efficiency?

Inspecting and lubricating blower motors and fan assemblies preserves optimal airflow, reduces energy draw, and prevents belt slippage or bearing failure. Ensuring balanced fan blades maintains consistent air distribution throughout ductwork.

What Role Does Ductwork Inspection Play in Preventing Energy Loss?

Leaky or obstructed ductwork can squander up to 30 percent of conditioned air. Inspecting seams, sealing gaps with mastic, and removing blockages in flexibility or rigid ducts restores design airflow and prevents energy waste. Ductwork repair is essential for maintaining efficiency.

How Can Commercial AC Service Contracts Support Consistent Tune-Ups and Energy Savings?

Service contracts formalize maintenance schedules, guaranteeing regular tune-ups and predictable costs.

What Are the Key Benefits of Commercial HVAC Maintenance Agreements?

Service agreements deliver several advantages:

- Proactive Scheduling ensures tune-ups occur before peak seasons.

- Fixed Maintenance Pricing protects against rate spikes.

- Priority Emergency Response reduces downtime during failures.

- Detailed Service Reports document performance trends over time.

This framework provides peace of mind and stable budgeting for facility managers.

What Should Businesses Look for in a Commercial AC Service Contract?

When evaluating contracts, prioritize:

- Comprehensive Coverage of all core components.

- Clear Response Times for emergency calls.

- Customized Service Intervals based on equipment age and usage.

- Performance Guarantees or energy-saving commitments.

- Transparent Reporting with data on efficiency gains.

Selecting the right contract aligns maintenance with business objectives and energy goals.

When Should You Call a Professional Commercial AC Technician for Tune-Ups and Repairs?

While many tune-up tasks are routine, certain signs warrant expert intervention to prevent system compromise.

What Are the Signs That Indicate the Need for Expert Commercial AC Service?

Recognize these red flags as triggers for professional diagnostics:

- Persistent temperature swings despite thermostat adjustments

- Unusual sounds such as grinding, rattling, or hissing

- Rapid frost buildup on refrigeration lines

- Water pooling around equipment

- Spikes in energy bills without changes in usage patterns

Addressing these symptoms promptly preserves equipment health and energy performance.

How Do Technicians Perform Diagnostics to Prevent Costly Commercial AC Repairs?

Technicians deploy advanced tools and methodologies to pinpoint hidden issues before failures occur:

- Infrared Thermography to detect hot spots and airflow problems

- Pressure and Vacuum Testing for leak verification

- Vibration Analysis on motors and fans to identify bearing wear

- Oil and Refrigerant Sampling to assess contamination or degradation

These diagnostic protocols support targeted repairs and long-term reliability.

What Are the Most Common Commercial AC Problems Prevented by Regular Tune-Ups?

Routine maintenance directly counters the key issues that degrade system performance and comfort.

How Do Tune-Ups Address Commercial AC Cooling Inefficiencies?

Tune-ups reverse cooling capacity losses by restoring clean heat exchangers and verifying correct refrigerant charge. Common inefficiencies resolved include sluggish temperature drops and uneven zone cooling.

What Causes Strange Noises and How Can Maintenance Fix Them?

Mechanical noises often arise from loose mounting hardware, worn bearings, or unbalanced fan blades. During a tune-up, technicians tighten fittings, lubricate moving parts, and adjust fan balance to silence these disturbances.

How Does Preventative Maintenance Reduce Water Leaks and Electrical Issues?

Clearing blocked drain lines prevents condensate overflow, while securing electrical connections and replacing aged components eliminates shorts and circuit tripping. This combined approach safeguards both moisture control and electrical integrity.

How Do Different Commercial AC System Types Affect Tune-Up Procedures?

Tune-up requirements vary according to system architecture, from rooftop packages to sophisticated VRF installations.

What Are the Tune-Up Differences for Rooftop Units vs. Split Systems?

Rooftop units house compressors, coils, and blowers in a single assembly on the roof, requiring safe access, weatherproof inspections, and canopy integrity checks. Split systems separate indoor evaporator coils and air handlers from outdoor condensers, demanding coordinated servicing of ductwork, drain lines, and refrigerant piping.

| System Type | Tune-Up Focus | Key Considerations |

|---|---|---|

| Rooftop Unit | Unit enclosure, roof seals | Weatherproofing, safe roof access |

| Split System | Indoor coil access, line sets | Insulation integrity, indoor-outdoor calibration |

These distinctions ensure tailored procedures for each configuration.

How Are Variable Refrigerant Flow (VRF) Systems Maintained for Energy Efficiency?

VRF maintenance entails multi-zone refrigerant balancing, micro-channel coil cleaning, and controller software updates. Technicians verify branch-circuit temperatures, sensor calibration, and connectivity between indoor units and the outdoor condensing module to optimize system-wide performance.

Maintaining each AC system type according to its design characteristics establishes a foundation for reliable, efficient cooling no matter the installation style.

Proactive tune-ups deliver measurable energy savings, extended equipment life, and uninterrupted comfort. By following these five must-do steps, supplementing with essential care tasks, leveraging service contracts, and understanding when to call in professionals, commercial property owners can safeguard operations and achieve sustainable cost control. Integrating these best practices with expert

ensures every system performs at its peak throughout the summer season.

Frequently Asked Questions

What are the signs that my commercial AC system needs a tune-up?

Signs that your commercial AC system requires a tune-up include inconsistent temperatures throughout the building, unusual noises like grinding or hissing, and visible frost on refrigerant lines. Additionally, if you notice water pooling around the unit or a sudden spike in energy bills without any changes in usage, these are clear indicators that professional maintenance is needed. Addressing these issues promptly can prevent further damage and ensure efficient operation.

How often should commercial AC systems undergo tune-ups?

Commercial AC systems should ideally undergo tune-ups at least twice a year, typically before the peak summer and winter seasons. This proactive approach helps ensure that the system operates efficiently and reliably when it is needed most. However, facilities with high occupancy or specific environmental conditions may benefit from more frequent maintenance. Regular tune-ups help identify potential issues early, extending the lifespan of the equipment and improving energy efficiency.

Can I perform AC maintenance tasks myself, or should I hire a professional?

While some basic maintenance tasks, such as changing air filters and cleaning debris from outdoor units, can be performed by facility staff, many tasks require specialized knowledge and tools. Professional technicians are trained to conduct thorough inspections, identify hidden issues, and perform complex repairs safely. Hiring a professional ensures that all components are properly maintained, which is crucial for system efficiency and longevity.

What is the role of service contracts in commercial AC maintenance?

Service contracts play a vital role in ensuring consistent maintenance for commercial AC systems. They provide scheduled tune-ups, fixed pricing for services, and priority emergency response, which can significantly reduce downtime during failures. Additionally, these contracts often include detailed service reports that help track system performance over time, allowing facility managers to make informed decisions about their HVAC systems and budget effectively for maintenance costs.

How do different types of commercial AC systems affect maintenance procedures?

Different types of commercial AC systems, such as rooftop units, split systems, and VRF systems, have unique maintenance requirements. Rooftop units require inspections for weatherproofing and safe access, while split systems necessitate coordinated servicing of indoor and outdoor components. VRF systems involve multi-zone refrigerant balancing and software updates. Understanding these differences ensures that maintenance procedures are tailored to each system’s design, optimizing performance and energy efficiency.

What additional tasks can enhance the performance of my commercial AC system?

In addition to the five core tune-up steps, several supplemental tasks can enhance the performance of your commercial AC system. These include cleaning the drain line to prevent clogs, inspecting and lubricating blower motors for optimal airflow, and checking ductwork for leaks or obstructions. Addressing these areas can significantly improve energy efficiency, reduce operational costs, and extend the lifespan of the equipment, ensuring reliable cooling throughout the summer months.

Conclusion

Proactive tune-ups deliver measurable energy savings, extended equipment life, and uninterrupted comfort. By following these five must-do steps, supplementing with essential care tasks, leveraging service contracts, and understanding when to call in professionals, commercial property owners can safeguard operations and achieve sustainable cost control. Integrating these best practices with expert commercial AC services ensures every system performs at its peak throughout the summer season. Explore our range of commercial AC maintenance solutions to enhance your system’s efficiency today.