Hydronic boiler repair: 5 Essential Tips for Comfort

Why Hydronic Boiler Repair Demands Specialized Expertise

Hydronic boiler repair requires a unique blend of plumbing and HVAC expertise. When your building’s water-based heating system fails, you need professionals who understand these specific systems, not a generalist who primarily works on furnaces or air conditioners.

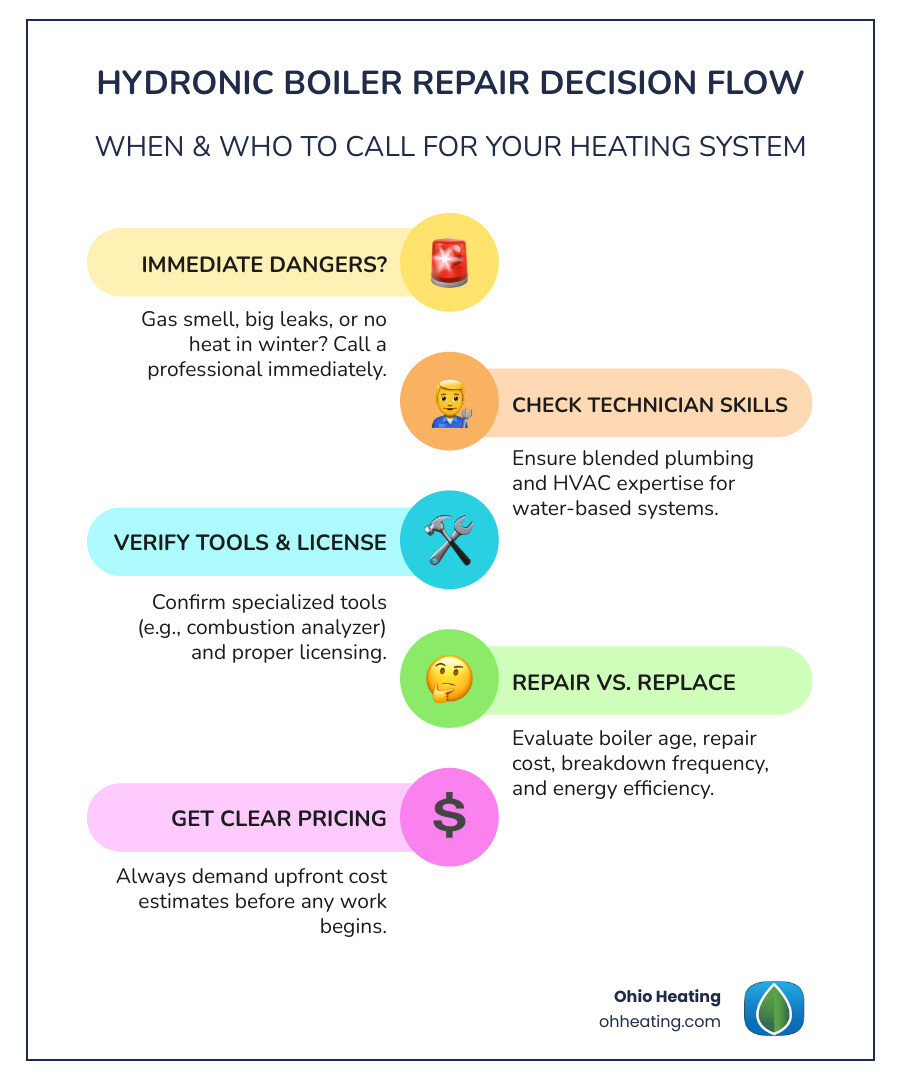

Quick Answer: Finding the Right Hydronic Boiler Repair Service

- Look for blended expertise – The technician should have both plumbing and HVAC skills.

- Verify specialized tools – They should carry multimeters, manometers, and combustion analyzers.

- Check licensing – Ensure proper credentials for working on both heating systems and plumbing connections.

- Confirm experience – Ask if they routinely service hydronic systems.

- Request upfront pricing – Reputable services provide clear cost estimates before starting work.

Hydronic heating systems work by circulating heated water through pipes to radiators or in-floor tubing. This creates comfortable, energy-efficient warmth without blowing air or dust. The system is quiet, allergy-friendly, and provides superior comfort compared to forced-air heating.

When something goes wrong, the complexity of these systems becomes apparent. Modern high-efficiency boilers have sophisticated controls that demand technical expertise beyond basic HVAC work. Many companies attempt boiler installations but lack skill in key areas like gas piping and water connections, creating more problems for property owners.

The stakes are high. A failed heating system in winter can lead to frozen pipes, property damage, unhappy tenants, and lost revenue. That’s why knowing who to call for professional help matters tremendously.

Recognizing the Red Flags: Common Boiler Problems and Warning Signs

Your hydronic boiler works hard, and recognizing early warning signs of wear can save you from expensive hydronic boiler repair down the line.

Here are common red flags that indicate your boiler might need attention:

- No heat or insufficient heat: The most obvious sign. If your home isn’t getting warm, or some areas are cold, your boiler is struggling.

- Uneven heating: If one room is toasty and another is chilly, it could point to issues with zone valves, air in the system, or circulation problems.

- Strange noises (kettling, gurgling, banging): Kettling (a whistling sound) often indicates mineral buildup, while gurgling or banging can mean air in the system or circulation issues.

- Visible water leaks or pooling: Any sign of water around your boiler is a serious concern that needs immediate attention to prevent damage.

- Pilot light issues: If your pilot light frequently goes out or isn’t blue, it signals a problem with the gas supply or thermocouple.

- Unexpectedly high energy bills: A boiler that is losing efficiency works harder, consuming more fuel and driving up your utility costs.

- Frequent cycling: If your boiler turns on and off more often than usual, it could be short cycling due to various internal problems.

Key Components Prone to Failure

Hydronic systems have specialized parts, and some are more susceptible to wear. Understanding these helps us diagnose issues quickly during hydronic boiler repair.

- Circulator pump: The heart of your system, it moves heated water. Failures like seized bearings or blockages lead to no heat or uneven heating. A grinding noise is a common sign of trouble.

- Expansion tank: This tank accommodates expanding hot water to prevent pressure buildup. A failing tank can cause the pressure relief valve to activate frequently or lead to leaks.

- Zone valves: These control heat to different areas. If a specific zone isn’t heating, a faulty zone valve may be the culprit.

- Thermocouples: In boilers with standing pilot lights, a thermocouple detects the flame. If it fails, the pilot light won’t stay lit.

- Aquastats: These controls monitor water temperature. A malfunction can lead to inconsistent heating or a boiler that runs continuously.

- Low water cutoff valve: This safety device shuts the boiler down if water levels are too low, preventing overheating. Failure can cause a complete shutdown.

When to Call for Professional Hydronic Boiler Repair

While some minor issues can be troubleshooted, certain warning signs demand an immediate call to our professional team for your safety.

Here are 5 critical warning signs that mean you need to call us right away:

- Smell of gas: If you detect a gas odor, turn off your boiler, open windows, avoid using electrical switches, and call your gas company’s emergency line. Once the area is safe, contact us.

- Major water leaks: Significant pooling water could indicate a serious internal problem that requires immediate attention to prevent extensive damage.

- No heat in winter: In Columbus, Ohio, a lack of heat can be dangerous, potentially leading to frozen pipes.

- Carbon monoxide detector alarm: If your CO detector goes off, evacuate immediately and call emergency services. Once safe, we can inspect your boiler for combustion issues.

- Electrical issues: Sparks, burning smells, or frequent circuit breaker trips indicate a dangerous electrical problem that requires an expert.

Before You Call: DIY Troubleshooting and Proactive Maintenance

When your heating stops working, it’s easy to panic. But before scheduling hydronic boiler repair, there are several safe, simple troubleshooting steps you can try.

Safety always comes first. If you smell gas, see sparks, or suspect an electrical hazard, follow the critical warning signs we covered earlier and call for professional help immediately.

With no immediate safety concerns, start with the basics. Check your thermostat settings. Is it set to “heat”? Is the temperature set higher than the current room temperature? Dead batteries in a wireless thermostat are also a common culprit.

Next, inspect around your boiler for obvious leaks. Look at the floor and along the pipes for dripping or pooling water. A significant leak means you should call us right away.

Now check your boiler’s pressure gauge. This circular dial on the front of your boiler should typically read between 12-15 PSI when the system is cold. If the pressure is too low, the boiler may not fire up. If it’s in the red zone, you could have an expansion tank issue. Knowing the reading helps us diagnose the problem faster.

Many boilers have a reset button. Locate the button (check your owner’s manual) and press it once. Give the boiler a few minutes to restart. Do not press it repeatedly; if it keeps shutting down, it indicates a deeper problem that needs professional attention.

How to Address Air in the Hydronic System

Air trapped in the system is a common issue, causing gurgling sounds or cold spots on radiators. Bleeding your radiators releases this air.

First, locate the bleeder valves on your radiators, which are small valves usually at a top corner. You’ll need a radiator key or a flathead screwdriver to open it.

Here’s the step-by-step process: Turn off your heating system and let it cool. Place a cloth under the valve to catch water. Slowly turn the key counter-clockwise until you hear hissing air. Keep the valve open until water comes out steadily, then turn the key clockwise to close it. Repeat for all radiators, starting with those closest to the boiler.

After bleeding, check your boiler’s pressure gauge. The process can lower system pressure, so you may need to add water to bring it back to the recommended range.

If gurgling sounds persist or you have to bleed radiators frequently, it’s time to call us, as a larger issue may be introducing air into your system.

The Power of Prevention: How Routine Maintenance Saves Money

Annual boiler maintenance is the best way to save money and avoid headaches. We recommend scheduling a tune-up at least once a year, ideally in early fall before winter arrives in Central Ohio. This ensures your system is ready when you need it most.

Regular maintenance extends your boiler’s lifespan. A well-maintained boiler can last 20-30 years, while a neglected one might fail in half that time. It also improves efficiency, as our technicians clean components and perform calibrations to keep your boiler running at peak performance, lowering your utility bills.

Most importantly, professional maintenance prevents costly emergency breakdowns. During a tune-up, our NATE-certified technicians use specialized tools like combustion analyzers to catch small problems before they become major failures. A minor fix during routine maintenance is always cheaper than an emergency repair during a snowstorm.

This proactive care gives you peace of mind, knowing your boiler is safe, efficient, and reliable. For those interested in the technical details, this comprehensive guide to boiler diagnosis and repair offers more insight.

Professional Hydronic Boiler Repair: When and Who to Call

When DIY troubleshooting fails or you face a critical warning sign, it’s time for professional hydronic boiler repair. Attempting complex repairs without proper training can be dangerous and expensive.

Modern high-efficiency boilers are sophisticated machines. Our technicians use advanced diagnostic equipment like multimeters, manometers, and combustion analyzers to accurately pinpoint problems. These specialized tools are essential for proper calibration and comprehensive safety checks, ensuring your boiler burns fuel safely and efficiently.

Safety is our top priority. Your boiler involves combustible fuels, high temperatures, and pressurized water. A wrong move can lead to gas leaks, carbon monoxide poisoning, or severe water damage. Our licensed and insured technicians follow strict protocols to protect your home and family.

Furthermore, DIY repairs or hiring an unqualified person can void your boiler’s warranty. Professional service ensures all work meets manufacturer standards, protecting your investment.

The Big Decision: Repair vs. Replace Your Boiler?

Deciding whether to repair or replace your boiler is a common question that depends on several factors. This table breaks down the key considerations.

| Factor | Repair | Replace |

|---|---|---|

| Age of Boiler | Generally for boilers under 10-15 years old | Recommended for boilers 15+ years old, or especially 35+ years old for efficiency |

| Repair Cost | Cost-effective for minor, infrequent repairs | Consider if repair cost exceeds 1/3 the price of a new unit |

| Frequency of Breakdowns | Occasional, isolated incidents | Frequent breakdowns indicate systemic issues and impending failure |

| Energy Efficiency | Older boilers are inherently less efficient | New, high-efficiency models offer significant energy savings and lower utility bills |

Boiler lifespan is a primary consideration. A typical boiler lasts 15-20 years, though some older cast-iron models can last over 30 years with diligent maintenance. If your boiler is approaching or past this age, replacement is often the sensible choice.

We use the 1/3 rule as a guideline: if repairs exceed one-third of the replacement cost, we typically recommend replacement. This is because in an aging boiler, one major component failure is often followed by others.

An expired warranty means you are responsible for all parts and labor. For older units, parts can also be difficult to find. The energy efficiency gains from a new boiler can be substantial, with a modern unit often paying for itself over time through lower energy bills.

Plumber vs. HVAC Tech: Who’s the Right Pro for Your Hydronic Boiler Repair?

Homeowners often wonder whether to call a plumber or an HVAC tech. For hydronic systems, the answer is a professional with blended expertise.

Hydronic boiler repair demands specialized skills in both plumbing and HVAC. Technicians must understand water pressure, expansion tanks, and circulation (plumbing) as well as low-voltage controls, combustion, and heat distribution (HVAC). At Ohio Heating, our technicians have had this crucial dual expertise since 1999.

Specialized tools like manometers and combustion analyzers are another differentiator. Many general plumbers don’t carry this equipment, which is essential for safety and efficiency testing. Licensing requirements in Ohio also mandate specific credentials for working on systems connected to plumbing, ensuring the work is both legal and safe.

Modern boilers feature sophisticated low-voltage controls that require HVAC-related skills in wiring and system management. For reliable repair, you need a professional who bridges both worlds—and that’s what we provide at Ohio Heating.

Frequently Asked Questions about Hydronic Boilers

We get a lot of questions about hydronic heating systems. Here are answers to some of the most common ones we hear from homeowners in Central Ohio.

How often should my hydronic boiler be serviced?

At least once a year. The best time for maintenance is in the fall, before the Columbus winter arrives. An annual check-up ensures your boiler is ready for the cold, and it’s also critical for safety. Regular service catches potential carbon monoxide risks and other hazards, extends your boiler’s lifespan, keeps it running efficiently to lower energy bills, and is often required to keep your manufacturer’s warranty valid.

What are the typical costs associated with a boiler repair service call?

We believe in cost transparency. A hydronic boiler repair visit typically starts with a service call fee for travel and diagnostics. The total cost then depends on the labor rates for the repair’s complexity and the parts costs, which can vary significantly. What sets us apart is our commitment to upfront pricing. Before we begin any work, we’ll explain the problem and provide a clear, complete cost estimate. You’ll have all the information to make a decision with no hidden fees.

Is it worth repairing a boiler that is over 15 years old?

This is a great question, and the answer is: it depends. A 15-year-old boiler doesn’t automatically need replacement, but it requires careful evaluation. The key factors are its condition, repair history, and the cost of the repair.

If your well-maintained boiler needs its first major repair, fixing it might be the right choice. However, if you’re facing frequent breakdowns, the costs are adding up. We often use the one-third rule: if a repair costs more than a third of a new boiler’s price, replacement is usually more financially sound.

Efficiency is also a major factor. A new high-efficiency boiler can dramatically lower your energy bills, with the savings potentially paying for the new unit over time. When you call us for hydronic boiler repair, we’ll honestly assess your system and help you weigh all the options for your home and budget.

Conclusion: Trust the Experts for Reliable Warmth

Your hydronic boiler is the quiet champion of your home’s comfort, but when something goes wrong, you need a solution you can trust. We’ve covered the warning signs your boiler needs attention, the simple troubleshooting you can do yourself, and the critical moments when it’s time to call in professionals for hydronic boiler repair.

Hydronic systems are sophisticated, demanding specialized knowledge that bridges both plumbing and HVAC. Safety is paramount, and proper service requires specific tools and expertise to prevent hazards like carbon monoxide leaks or gas connection issues.

We’ve also helped you weigh the tough repair-or-replace decision, considering your boiler’s age, repair costs, and the potential energy savings of a new unit. Investing in your heating system is about protecting your home, your family, and your budget.

At Ohio Heating, we’ve been keeping Columbus-area homes and businesses warm since 1999. Our NATE-certified technicians understand hydronic systems inside and out. We are committed to providing timely, professional service that restores your comfort and gives you peace of mind.

Don’t wait for a small problem to become a winter emergency. Whether you need routine maintenance or an urgent repair, we’re here to help. Schedule your expert boiler sales and service today and experience the comfort of working with a team that truly cares.