AC compressor replacement: 2025 Risky DIY Guide

Understanding AC Compressor Replacement and Your Options

AC compressor replacement is one of the most significant and costly repairs you’ll face with your commercial or residential HVAC system, typically ranging from $2,100 to $5,200 for professional installation.

Quick Answer: Should You DIY AC Compressor Replacement?

- Professional Replacement Recommended: AC compressor replacement requires EPA certification, specialized tools ($500-$2,000), and technical expertise

- Average Cost: $2,100-$5,200 professionally installed vs. $800-$2,400 in parts alone for DIY

- Time Required: 4-8 hours for experienced DIYers, 1-2 hours for professionals

- Key Requirements: Refrigerant recovery machine, vacuum pump, manifold gauges, proper refrigerant handling certification

- Major Risks: System contamination, warranty void, refrigerant mishandling, personal injury

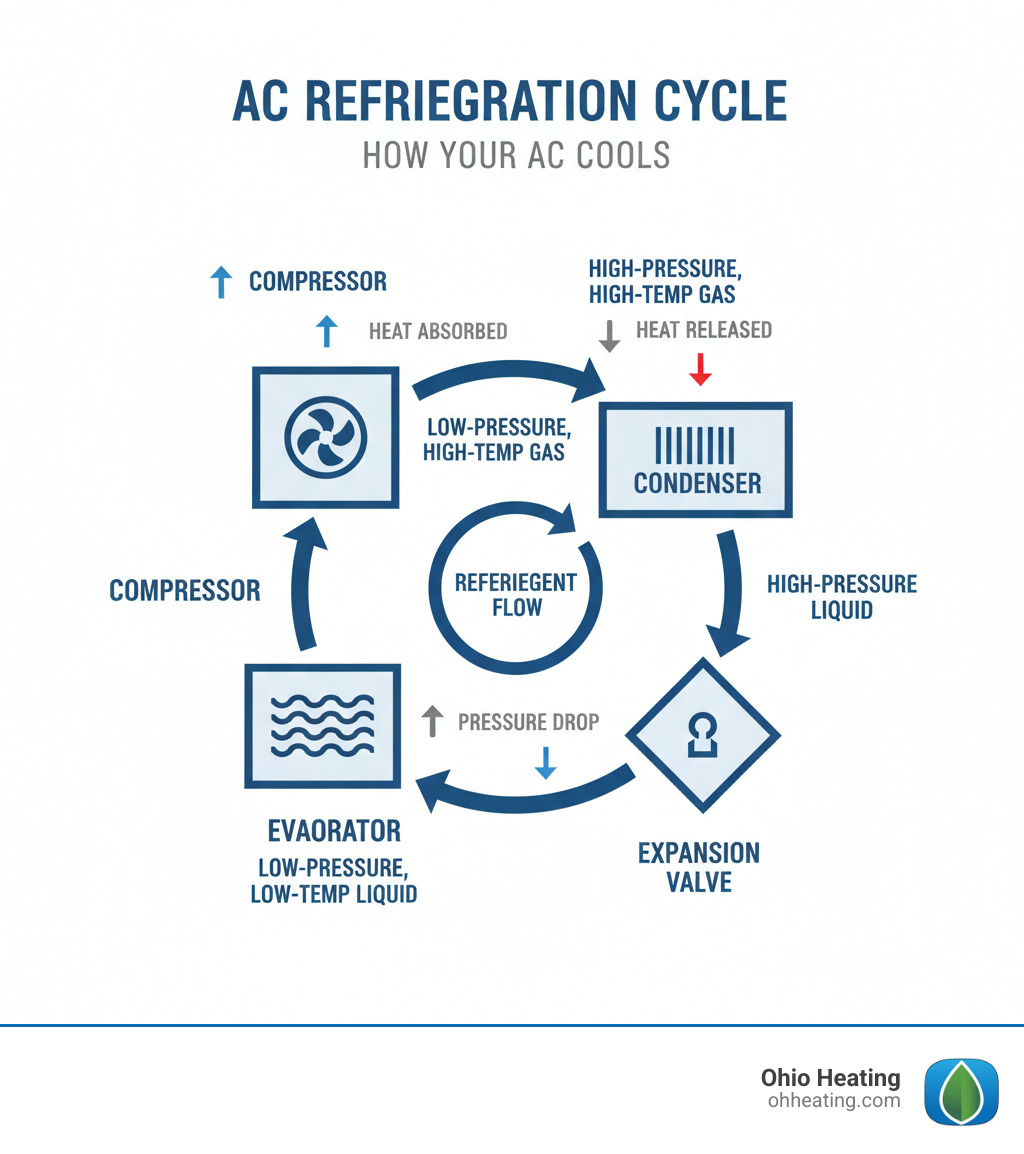

The AC compressor acts as the heart of your air conditioning system. It compresses refrigerant gas and circulates it through the system, making cooling possible. When this critical component fails, property managers and business owners face a difficult decision: attempt a DIY replacement to save on labor costs, or hire a licensed HVAC technician to ensure the job is done safely and correctly.

The debate isn’t just about money. It involves safety regulations, environmental compliance, specialized equipment, and the risk of causing additional damage to your system. A failed DIY attempt can easily turn a $2,000 repair into a $5,000+ system replacement.

This guide walks you through the entire AC compressor replacement process, helps you understand the real costs and risks involved, and provides the information you need to make the right choice for your property.

Recognizing and Diagnosing a Failing Compressor

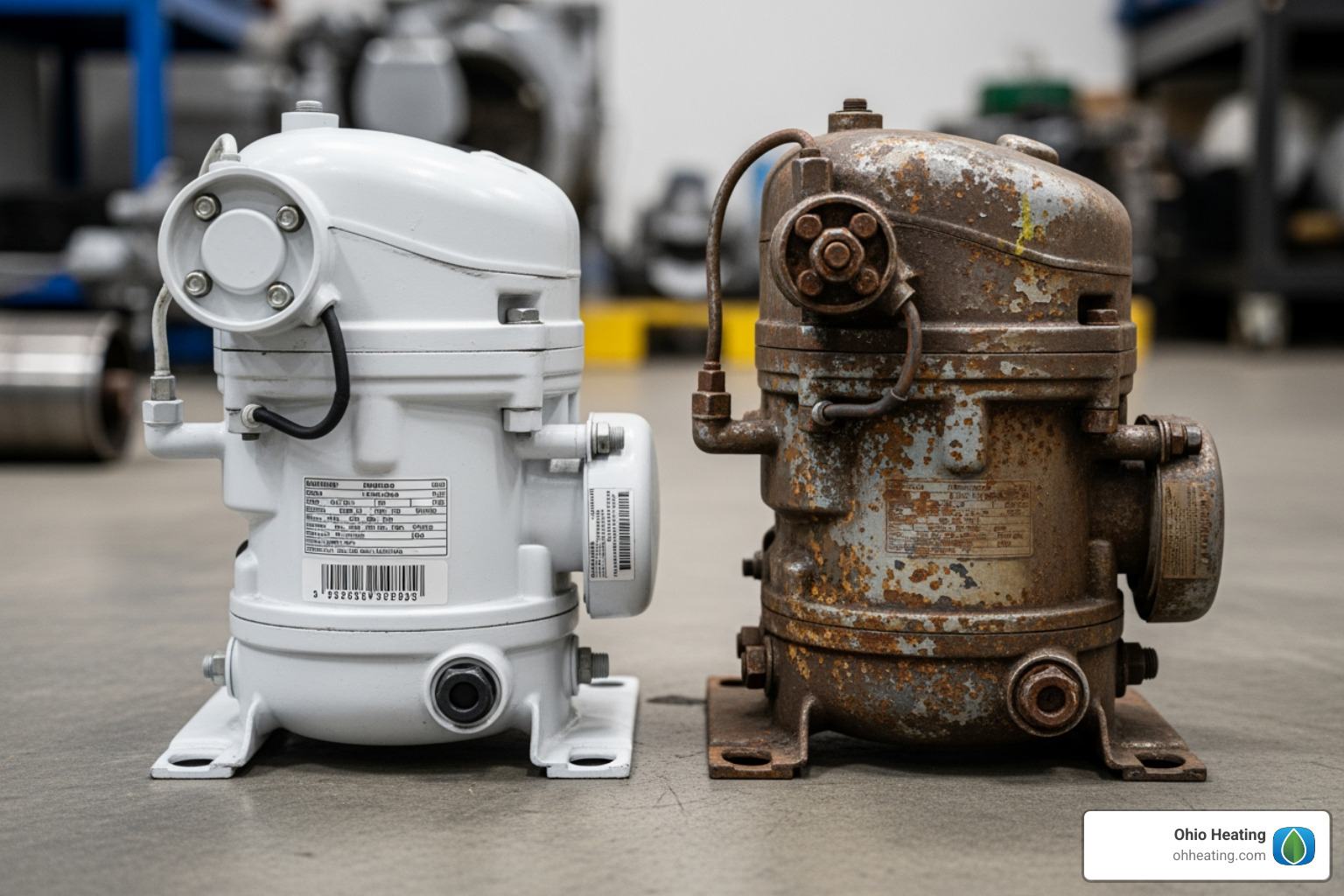

Before you even think about a DIY AC compressor replacement, it’s super important to figure out if your compressor is actually the problem. Many AC issues can trick you into thinking it’s the compressor when it’s something else entirely. A good diagnosis can save you a lot of time, money, and frustration down the road.

Think of your compressor as the heart of your AC system. Its main job is to pump refrigerant, turning a low-pressure gas into a high-pressure, hot gas to kickstart the cooling process. When this vital part starts to falter, your whole AC struggles to keep things cool.

Here are the common warning signs that your AC compressor might be giving up:

- Loud, Unusual Noises: This is often one of the first clues. If your outdoor unit starts making sounds you’ve never heard before, pay attention. We’re talking about grinding, squealing, rattling, or even a distinct knocking sound. These noises can hint at internal damage, worn-out bearings, or loose parts. Sometimes, it might just be a loose nut, but if the noise keeps up, it’s a strong sign of deeper trouble inside. For more details on what those strange sounds might mean, check out our guide on What Weird Noises from Your AC Unit Could Mean for Repairs.

- Reduced Cooling or Warm Air: Is your AC blowing air that just isn’t cold? Or maybe it’s barely cooling your Columbus, Ohio home or business at all? If the air feels warm or just lukewarm, your compressor could be the culprit. A failing compressor can’t properly pressurize the refrigerant, which throws off the entire cooling process.

- Frequent Cycling (Short Cycling): If your AC unit keeps turning on and off very quickly, it’s “short cycling.” This can happen for a few reasons, but a struggling compressor is a common one. It might be overheating or having electrical issues, forcing it to shut down too soon.

- Tripped Circuit Breaker: Your AC compressor uses a lot of electricity. If it’s failing, it might try to pull too much power, causing your circuit breaker to trip over and over again. This could also mean there’s an electrical problem within the compressor itself, like a motor struggling to start.

- Refrigerant Leaks: While leaks don’t always come directly from the compressor, they can certainly be linked. Sometimes, leaks lead to low refrigerant levels, which then put a huge strain on the compressor, causing it to fail. Look for oily stains around your outdoor unit, as refrigerant oil often leaks out with the refrigerant.

- Non-Moving Clutch (for some older models): If your AC unit has a compressor clutch (common on older units), and you notice it’s not engaging when the AC is running, that’s a red flag. If the clutch doesn’t engage, the compressor can’t do its job.

To truly get to the bottom of a bad AC compressor, a professional HVAC technician has a few tricks up their sleeve. They’ll start with a visual inspection, looking for obvious signs like leaks, damaged wires, or a clutch that won’t engage. Then, they’ll be listening carefully to pinpoint where any unusual sounds are coming from. They’ll also check the refrigerant pressure using special manifold gauges to measure the high and low-side pressures. Odd pressures (either too high or too low) can point to a compressor issue, or perhaps a blockage elsewhere. Finally, they’ll perform electrical checks to make sure the compressor is getting the right amount of power.

A failing compressor isn’t just about losing your cool air; it can also put a lot of stress on the other parts of your AC system. This can lead to more costly repairs and even higher utility bills down the line. That’s why getting an accurate diagnosis right from the start is the most important step!

The DIY AC Compressor Replacement Process: A Step-by-Step Guide

So, you’ve diagnosed a failing compressor, and you’re thinking about tackling a DIY AC compressor replacement yourself. We understand the appeal of saving on labor costs, especially when faced with a significant repair bill. However, it’s crucial to be fully aware of just how intricate this task is, the specialized tools it demands, and the serious risks involved. This isn’t a project for the inexperienced or someone without a deep understanding of HVAC systems.

Before you even think about picking up a wrench, your safety must come first. Safety precautions are paramount. Always, always, turn off the power to your entire AC unit at the electrical panel. This isn’t just a suggestion; it’s non-negotiable for your personal safety. You should also wear protective gear like safety goggles and gloves to guard against refrigerant splashes, sharp edges, and potential electrical hazards. Refrigerant is a hazardous substance. Mishandling it is not only dangerous but also illegal.

Now, about those tools. You’ll need much more than just a basic toolbox for this job. Think about having a comprehensive wrench and socket set, your trusty screwdrivers, and pliers. But the real specialized items are an AC manifold gauge set, a refrigerant recovery machine and tank (which can be a significant investment!), and a vacuum pump. Of course, you’ll need the new replacement compressor itself. It’s also highly recommended to replace accompanying parts like a new receiver drier/accumulator and the expansion valve/orifice tube. Don’t forget fresh replacement O-rings and seals, the correct type of refrigerant oil, and the right kind of fresh refrigerant for your system.

Here’s a general look at the DIY steps involved in an AC compressor replacement:

Step 1: Recover the Refrigerant

This step is arguably the most critical part of the process, and it’s heavily regulated by law. Refrigerant is a powerful greenhouse gas. Releasing it into the atmosphere isn’t just bad for the environment; it’s strictly illegal.

The Environmental Protection Agency (EPA) has very strict rules about how refrigerant is handled. To even recharge refrigerant, the person doing the work needs to hold specific Environmental Protection Agency (EPA) certification requirements. This is why a professional is almost always necessary for this step, even if you plan to do other parts yourself. You absolutely must use a specialized refrigerant recovery machine to safely take the refrigerant out of your AC system and store it in a special tank. This equipment is expensive, often costing hundreds or thousands of dollars, which usually makes it impractical for a one-time DIY project. Trying to vent refrigerant into the air, or using the compressor itself to get rid of air, is against the law and will likely damage your system.

Step 2: Remove the Old Compressor

Once the refrigerant has been safely removed from your system, you can move on to taking out the faulty compressor.

First, double-check that the power to the outdoor unit is completely off at the electrical panel. Safety first! Next, carefully remove the access panels on your outdoor unit. This will expose the compressor and all its connections. Then, you’ll need to disconnect the refrigerant lines (the suction and discharge lines) that connect directly to the compressor. Be ready for any leftover refrigerant or oil that might still escape, even after recovery. The compressor is typically held in place by several bolts at the base of the unit. Go ahead and unbolt the compressor. While most residential AC units don’t have a drive belt like a car, some systems might have other components you need to move to get good access.

Step 3: Install the New Compressor

This is the exciting part where your AC system gets its new “heart” installed!

Before you do anything else, carefully compare your new compressor to the old one. Make sure they have the same setup, compatible refrigerant ports, and the correct electrical connections. A mismatch here can lead to immediate failure or even damage your entire system. Now, gently mount the new compressor into its spot, lining it up with the mounting bolts. Once it’s in place, secure it tightly. Next, reconnect the refrigerant lines to the new compressor. This is a super important step to prevent leaks down the road. Always replace the old O-rings and seals with brand-new ones at every connection point. Make sure to lubricate them with the right kind of refrigerant oil for a snug, leak-free seal. Finally, reconnect the electrical wiring harness to the new compressor, ensuring all connections are secure and match the original setup perfectly.

Step 4: Evacuate and Recharge the System

After your new compressor is in place, your system isn’t quite ready to cool yet. It absolutely must be properly evacuated and then recharged.

You’ll need to use a vacuum pump to evacuate the system before you introduce any new refrigerant. This process is vital because it removes all air and moisture from the lines. If any moisture is left in the system, it can freeze, cause corrosion, and severely damage your new compressor and other components. Once the system is under a deep vacuum, you can then recharge it with the correct type and amount of refrigerant. Knowing your system’s specific requirements (like R-22 or R-410A) is crucial here. Putting in too much or too little refrigerant can lead to inefficient operation or even damage. After recharging, use your manifold gauges to check the system’s high and low-side pressures. These readings should fall within the manufacturer’s specified ranges for your AC to perform optimally. You’ll also need to check for any leaks one last time.

As you can see, this entire process is highly technical and demands precision. Even a small mistake can lead to significant problems, which brings us to our next important discussion.

DIY vs. Professional: Weighing the Risks and Rewards

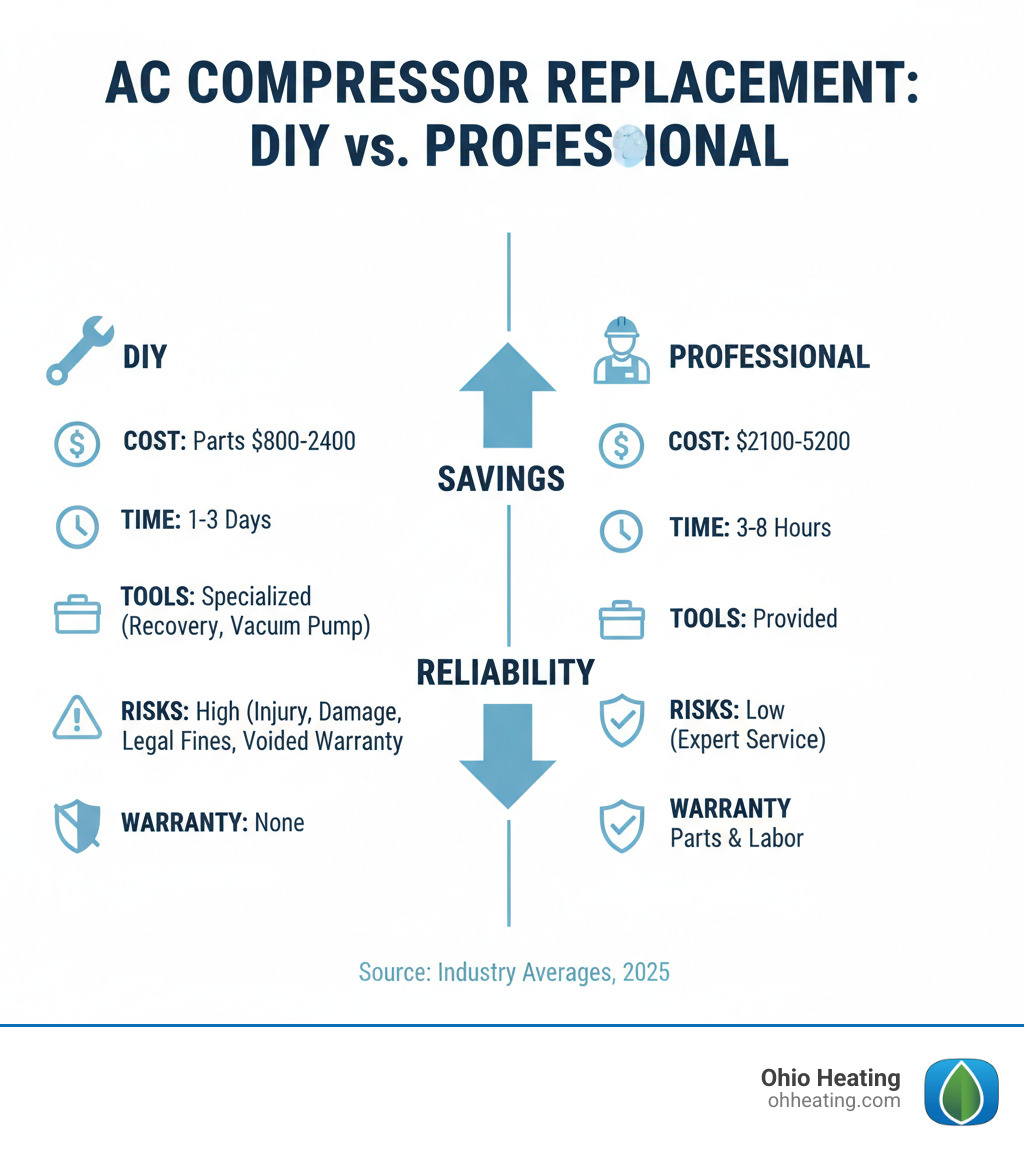

When faced with a major repair like AC compressor replacement, the choice between DIY and hiring a professional is a tough one. While the allure of saving money on labor is strong, the complexities often outweigh the perceived benefits.

Here’s a comparison to help you decide:

| Feature | DIY AC Compressor Replacement | Professional AC Compressor Replacement |

|---|---|---|

| Cost | $800 – $2,400 (parts only) | $2,100 – $5,200 (parts & labor) |

| Time | 4-8 hours (or more for beginners) | 2-4 hours |

| Tools & Equipment | High upfront cost ($500 – $2,000+) for specialized tools like a recovery machine and vacuum pump. | Technician arrives with all necessary professional-grade tools. |

| Risks | High risk of personal injury, system damage, refrigerant leaks, and voiding warranties. Potential for costly mistakes. | Low risk. Professionals are insured, trained, and guarantee their work. |

| Warranty | Voids manufacturer and home warranties. No guarantee on the repair. | Preserves existing warranties. Reputable companies like Ohio Heating offer a warranty on their labor and parts. |

When it comes to AC compressor replacement, the decision to DIY or hire a professional is a significant one. While the potential for cost savings is tempting, it’s crucial to weigh that against the substantial risks and requirements. For most homeowners and property managers in Columbus, Ohio, the complexity, safety concerns, and legal requirements make professional installation the smarter, safer, and ultimately more cost-effective choice. You can learn more about making this decision by reading our guide on whether to Find Out Whether to Repair or Replace Your Air Conditioning Unit.

What are the risks and benefits of DIY AC compressor replacement?

- Benefits: The primary benefit is cost savings on labor. For those with significant HVAC experience, there’s also the satisfaction of completing a complex repair yourself.

- Risks: The risks are substantial and can quickly negate any potential savings:

- System Damage: Incorrect installation, introducing moisture or contaminants, or using the wrong refrigerant can destroy your new compressor and other components, leading to a full system replacement.

- Personal Injury: You’re working with high-voltage electricity and pressurized refrigerant, which can cause severe burns, electrocution, or other injuries.

- Legal & Environmental Penalties: Venting refrigerant is illegal under EPA regulations and carries heavy fines. Proper handling requires certification and expensive equipment.

- Voided Warranties: Most manufacturers will void the warranty on the compressor and potentially the entire AC unit if it’s not installed by a licensed professional.

- Time & Frustration: What takes a pro a few hours can take a DIYer an entire weekend or longer, especially if unexpected issues arise.

When to hire a licensed HVAC technician

While the DIY spirit is admirable, an AC compressor replacement is one of those jobs best left to the professionals. You should always hire a licensed technician if:

- You are not EPA 608 certified to handle refrigerants.

- You don’t own or have access to a refrigerant recovery machine, vacuum pump, and manifold gauges.

- Your system is still under warranty.

- You are not completely comfortable working with high-voltage electrical systems.

Professionals undergo rigorous training and certification, for example, similar to the requirements outlined by the state of Michigan for licensed HVAC technicians. They have the right tools, the experience to diagnose the problem correctly, and the knowledge to ensure the replacement is done safely and to code. At Ohio Heating, our certified technicians have been serving the Columbus community since 1999, ensuring every job is done right the first time for your peace of mind and long-term system reliability. Why a licensed HVAC technician is crucial