Commercial ice maker repair near me: Top 5 Expert Fixes

Why Your Business Can’t Afford Ice Machine Downtime

Commercial ice maker repair near me is a critical search when your ice machine breaks down. Here’s what you need to know right now:

Quick Action Checklist:

- Identify the problem – No ice, low production, leaks, strange noises, or poor quality

- Find a qualified technician – Look for licensed, insured professionals with 24/7 availability

- Get transparent pricing – Request upfront quotes before any work begins

- Verify brand expertise – Ensure they service your specific ice machine brand (Hoshizaki, Manitowoc, Scotsman, etc.)

- Consider emergency service – Expect $150-$500 for emergency calls, plus parts and labor

A reliable supply of clean ice is the lifeblood of many businesses. Whether you run a restaurant, hotel, healthcare facility, or convenience store, a broken commercial ice machine means unhappy customers and lost revenue. Research shows that businesses in the hospitality industry can lose an average of $500 per day in revenue when their ice machine is down.

The good news? Most ice machine problems can be diagnosed and repaired quickly when you know the warning signs and have a trusted repair service on speed dial. Commercial ice machines typically last 10-15 years, and regular maintenance can extend that lifespan by up to 30%. Understanding when to repair versus replace, what to look for in a service provider, and how to prevent future breakdowns will save you time, money, and stress.

This guide provides the cold, hard facts on diagnosing issues, understanding your repair options, and finding expert commercial ice maker repair services in your area. You’ll learn to spot warning signs early, make smart financial decisions about repair versus replacement, and implement preventative care that keeps your ice flowing.

I’m Jill Frattini, a Service Coordinator at Ohio Heating in Columbus, OH, where I’ve spent several years helping businesses maintain their commercial refrigeration and HVAC systems. Through my work coordinating commercial ice maker repair near me calls and overseeing service projects, I’ve seen how quick action and the right expertise can prevent minor issues from becoming major disruptions.

Simple commercial ice maker repair near me glossary:

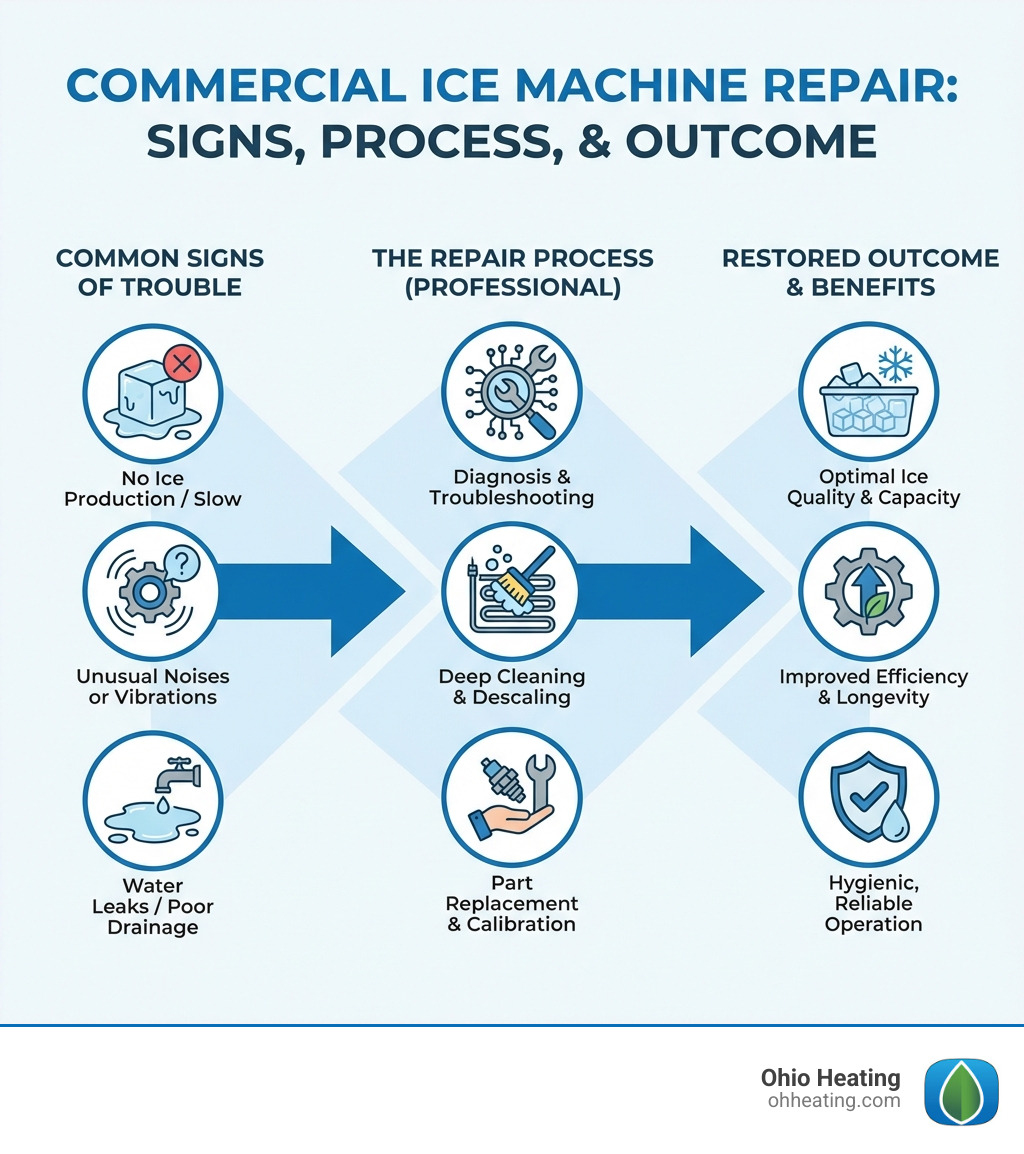

Is Your Ice Machine on the Fritz? Common Warning Signs

When your commercial ice machine starts acting up, it’s not just an inconvenience; it’s a direct threat to your bottom line. Catching the warning signs early can prevent a minor issue from escalating into a costly breakdown. We often encounter several common indicators that your ice machine needs professional attention. These include:

- No ice production: The most obvious sign. The machine is running, but no ice is being made, or the bin is empty.

- Low ice volume: If your machine is producing significantly less ice than its usual capacity (which can range from 50 to 1,000 pounds per day), it’s struggling.

- Machine is leaking water: Puddles around or under the unit are a clear red flag, indicating a potential issue with water lines, drains, or other internal components.

- Unusual noises: Grinding, squealing, buzzing, or loud clicking sounds are not normal and often point to mechanical problems.

- Poor ice quality: This can manifest as cloudy, discolored, or bad-smelling ice, or even misshapen or melting cubes.

- Unit is overheating: If the exterior of your ice machine feels unusually hot to the touch, it could indicate a problem with the refrigeration system working too hard.

Ignoring these signs can lead to further damage, increased repair costs, and prolonged downtime. As experts in commercial ice maker repair near me in Columbus and Central Ohio, we know that prompt diagnosis is key.

Decoding Alarming Noises and Leaks

Those strange sounds emanating from your ice machine are rarely a symphony of efficiency. They’re often distress signals from critical components. If you hear grinding or squealing, it could indicate issues with the motor or fan bearings. A loud clicking or buzzing might suggest a problem with the compressor or electrical relays. These sounds mean something is under strain or failing.

Water leaks are equally concerning. They can stem from various sources, such as:

- Water line leaks: Loose connections or damaged hoses can cause water to drip or spray.

- Clogged drain lines: If the drain line is blocked, water can back up and overflow, leading to leaks.

- Condenser pan issues: A cracked or overflowing condenser pan can also result in water on the floor.

- Fan motor problems: A failing fan motor can cause overheating, leading to ice melt and leaks.

These issues not only cause property damage but can also create slip hazards in your business. For a deeper dive into these and other potential problems, we encourage you to explore our guide on Common Ice Machine Problems: Know the Signs. If you’re experiencing any of these, don’t delay in seeking professional commercial ice maker repair near me.

Ice Quality Issues: From Bad Tastes to Wrong Shapes

The quality of your ice directly impacts your customers’ experience. If your ice tastes or smells bad, it’s often a sign of dirty water or internal contamination. This can be caused by:

- Mold or bacteria buildup: Over time, these can accumulate in the ice machine’s reservoir, lines, or bin, leading to unpleasant odors and tastes, sometimes even black debris in the ice.

- Dirty water: Contaminants, water deposits, or issues with your water source can affect the ice’s purity. A common culprit is a neglected water filter.

- Chemical exposure: Breaks in water lines or exposure to cleaning agents can introduce contaminants.

Cloudy or discolored ice typically points to high mineral content or sediment in your water supply. This can also indicate that your water filter needs changing or is no longer effective. Misshapen or small cubes, on the other hand, often signal problems with water flow, inconsistent temperatures, or clogged spray jets within the ice-making mechanism. These issues not only affect aesthetics but can also compromise the cooling efficiency of your beverages.

Identifying a Malfunctioning Compressor

The compressor is the heart of your ice machine’s refrigeration system, much like it is in an air conditioner. When it malfunctions, the entire ice production process is severely impacted. We’ve seen several key signs that indicate a compressor problem:

- Compressor fails to start: You might hear a click but no hum, or nothing at all, meaning the compressor isn’t initiating its cycle.

- Loud clicking or buzzing: This could be the compressor attempting to start but failing, or an electrical issue related to its operation.

- Unit runs constantly but doesn’t cool: The machine might be trying to make ice, but without a functioning compressor, the refrigerant cycle won’t properly cool the evaporator, resulting in no ice production.

- Reduced ice production: Even if some ice is being made, a weak compressor won’t be able to achieve the optimal cooling needed for full capacity.

- Overheating exterior: A compressor working too hard or inefficiently can generate excessive heat, making the machine’s exterior unusually warm.

Diagnosing a compressor issue requires specialized tools and expertise, as it’s a complex and high-pressure component. If you suspect a compressor problem, it’s crucial to call for professional commercial ice maker repair near me immediately to prevent further damage.

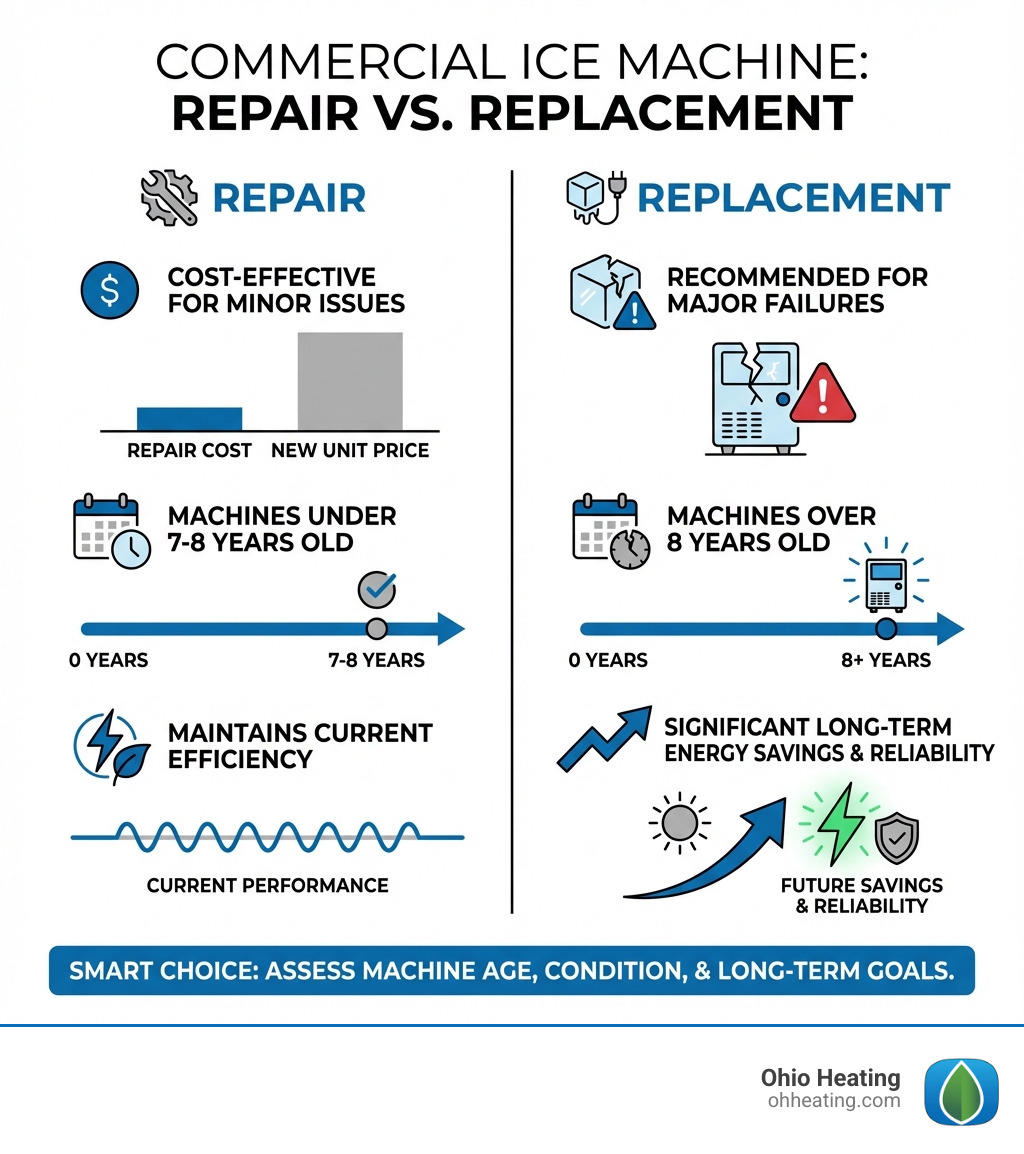

The Repair vs. Replacement Dilemma

When your commercial ice machine fails, you’re faced with a critical decision: repair or replace? This isn’t just about the immediate cost; it’s about long-term operational efficiency and financial sense. We often guide our clients through a careful cost-benefit analysis, considering several factors:

- Machine age and lifespan: The average lifespan of a commercial ice machine is 10-15 years. If your machine is approaching or has exceeded this age, replacement might be a more prudent investment.

- Frequency of breakdowns: A machine that constantly needs repairs is a money pit and a source of constant frustration and downtime.

- Energy efficiency of new models: Older machines are often less energy-efficient. New models can offer significant savings on utility bills, making replacement appealing.

- Availability of parts for older units: As machines age, finding replacement parts can become difficult and expensive, potentially leading to prolonged downtime.

Our rule of thumb, supported by industry insights, suggests that if the cost of repair exceeds 50% of the price of a new unit, replacement is generally the smarter choice.

What are the typical costs for a commercial ice maker repair near me?

Understanding the potential costs upfront helps you make informed decisions. Emergency commercial ice maker repair near me can typically cost between $150 to $500 for a service call, which usually includes the technician’s travel and initial diagnostic time. Beyond that, you’ll incur hourly labor rates, which vary by provider and the complexity of the job, plus the cost of any replacement parts.

We’ve also observed that external factors can impact repair costs and timelines. Recent global health crises, for instance, have led to parts shortages, which can delay services and even affect warranty repairs. This means that not only might parts be harder to find, but their cost could also increase. It’s why we emphasize working with a reputable company that has good relationships with suppliers and can quickly source necessary components.

When you’re looking for Commercial Ice Machine Sales and Repairs in Central Ohio, always ask for transparent, upfront pricing. A trustworthy provider will explain all charges before beginning work, ensuring no surprises.

When Is a Full Replacement the Smarter Choice?

While we always aim to repair and extend the life of your equipment, there are situations where a full replacement is undeniably the smarter, more cost-effective decision in the long run. We typically recommend considering replacement if:

- Repair cost exceeds 50% of a new unit’s price: As mentioned, this is a widely accepted industry benchmark. If a repair is that expensive, you’re better off putting that money towards a brand-new, warrantied machine.

- Frequent and recurring breakdowns: If your machine is constantly failing despite previous repairs, it’s a sign that it’s reached the end of its reliable service life. The cumulative cost and downtime will quickly outweigh the investment in a new unit.

- Obsolete technology: Older machines might use outdated refrigerants that are becoming phased out or difficult to source, making repairs challenging. They also lack the technological advancements of newer models.

- Desire for higher capacity or energy efficiency: If your business has grown and your current machine can’t keep up with demand, or if you’re looking to significantly reduce operating costs, a new, more efficient model can provide a strong return on investment. Upgrading to energy-efficient models can significantly reduce energy consumption and save you money in the long run.

Finding Commercial Ice Maker Repair Near Me: What to Look For

When you need commercial ice maker repair near me in Columbus or Central Ohio, choosing the right service provider is crucial. Not all repair companies are created equal. Here’s what we recommend you look for to ensure you get reliable, high-quality service:

- Licensed and insured technicians: This is non-negotiable. It protects you from liability and ensures the technicians are qualified to handle complex refrigeration systems.

- 24/7 emergency availability: Ice machine breakdowns don’t adhere to business hours. A company offering round-the-clock service can be a lifesaver, minimizing your downtime and revenue loss.

- Positive customer reviews: Check online reviews and testimonials. A strong reputation for professionalism, promptness, and effective repairs is a good indicator of quality service.

- Transparent, upfront pricing: Reputable companies provide clear, detailed quotes before any work begins, so you understand the costs involved without hidden fees.

- Guarantees on parts and labor: A good warranty on repairs demonstrates confidence in their workmanship and gives you peace of mind.

Essential Services Offered by Reputable Repair Companies

A comprehensive commercial ice maker repair near me company should offer more than just fixing broken parts. We believe in providing a full spectrum of services to keep your ice machine running optimally:

- Comprehensive diagnostics: Accurate problem identification is the first step to an effective repair. Technicians should use advanced tools to pinpoint the root cause of the issue.

- Professional cleaning and sanitation: Regular, thorough cleaning prevents mold, bacteria, and scale buildup, which are common causes of bad-tasting ice and machine inefficiency.

- Preventative maintenance programs: These proactive plans are designed to catch potential issues early, extend machine lifespan, and ensure consistent performance.

- New machine installation: When replacement is necessary, a reputable company should offer expert installation services, ensuring the new unit is set up correctly for optimal performance and longevity. Check out our services for Ice Machine Install and Service in Columbus.

- Emergency repair services: For those unexpected breakdowns, quick response times are essential to get your business back on track.

Brands and Expertise: Ensuring They Service Your Machine

Commercial ice machines come in a variety of brands and models, each with its own unique specifications and repair requirements. It’s vital to choose a service provider with experience across a wide range of manufacturers. We work with all major brands, and our technicians are often factory-trained, ensuring they have the specific knowledge needed for your equipment. We also have access to Original Equipment Manufacturer (OEM) parts, which are crucial for maintaining your machine’s integrity and warranty.

Some of the most commonly serviced commercial ice machine brands we encounter include:

Ensuring your chosen repair company is familiar with your specific brand means a faster, more accurate diagnosis and a more effective repair.

Proactive Care: Extending the Life of Your Ice Machine

A proactive approach to ice machine care is not just a recommendation; it’s a smart business strategy. Just as regular oil changes extend the life of your car, consistent maintenance significantly prolongs the operational life of your commercial ice maker. The benefits of regular ice machine maintenance are substantial:

- Extends lifespan up to 30%: Regular servicing can help your machine last years beyond its average 10-15 year lifespan.

- Prevents costly downtime: By catching small issues before they become major problems, maintenance minimizes unexpected breakdowns that can halt your operations and cost you hundreds of dollars a day.

- Improves energy efficiency: A well-maintained machine runs more efficiently, consuming less energy and lowering your utility bills.

- Ensures consistent ice quality: Regular cleaning and filter changes guarantee that your ice remains clean, clear, and free from odors or contaminants, upholding your business’s standards.

Investing in preventative measures is a small cost that yields significant returns, safeguarding your investment and ensuring a reliable ice supply.

The Ultimate Maintenance Checklist

While professional servicing is essential, there are several preventative measures you can take to contribute to your ice machine’s longevity and performance:

- Regularly clean air filters: Just like an HVAC system, your ice machine’s air filters can get clogged with dust and debris, reducing efficiency and potentially causing overheating. Clean them regularly according to manufacturer guidelines.

- Sanitize the bin and internal components: This is crucial for preventing mold, bacteria, and slime buildup, which can lead to bad-tasting ice and health concerns. Use approved sanitizers and follow proper cleaning procedures.

- Inspect water lines for leaks: Periodically check all visible water lines and connections for drips or signs of corrosion. Addressing small leaks quickly can prevent larger, more damaging issues.

- Schedule professional servicing twice a year: This is the gold standard. Professional technicians can perform deep cleaning, check refrigerant levels, inspect electrical components, and identify wear and tear that you might miss.

- Monitor ice production and quality: Pay attention to any changes in the amount of ice produced, its appearance, taste, or smell. These early indicators can signal a brewing problem.

The Critical Role of Installation and Water Filtration

The initial setup and ongoing water quality are paramount to your ice machine’s performance and maintenance. The installation location significantly affects how efficiently your machine operates:

- Proper ventilation requirements: Ice machines generate heat. They need adequate airflow around them to dissipate this heat. Restricting ventilation forces the machine to work harder, reducing efficiency and lifespan.

- Avoiding heat sources: Install your ice machine as far as possible from hot appliances like ovens, grills, and dishwashers, and away from direct sunlight or heat vents. High ambient temperatures make the machine struggle to cool, leading to reduced ice production and increased wear. We understand these challenges, especially during hot Ohio summers, and factor them into our recommendations.

- Importance of a high-quality water filter system: Water quality is perhaps the most overlooked aspect of ice machine maintenance. Untreated water can lead to:

- Scale buildup: Hard water minerals can accumulate on evaporator plates and other internal components, drastically reducing ice production and efficiency.

- Bad taste and smell: Contaminants, chlorine, and sediment in the water directly affect the taste and clarity of your ice.

- Increased wear and tear: Mineral deposits can clog lines and stress pumps, leading to premature component failure.

A good water filter system is an investment that pays for itself by preventing costly repairs, extending machine life, and ensuring high-quality ice. For more insights into these challenges, particularly in our region, refer to our article on Identifying Ice Machine Repair Challenges in Columbus.

Frequently Asked Questions about Commercial Ice Maker Repair

We often receive questions from business owners in Columbus and Central Ohio regarding their ice machines. Here are some of the most common ones we address:

How often should a commercial ice machine be professionally cleaned and serviced?

For most commercial ice machines, we recommend professional servicing and cleaning at least twice a year. This regular maintenance helps keep your machine running efficiently, prevents major breakdowns, and ensures the ice produced is safe and clean. For high-volume businesses, or those located in areas with particularly hard water, quarterly service may be necessary to prevent excessive scale buildup and maintain sanitation standards. This proactive approach saves you money in the long run by extending the machine’s lifespan and avoiding costly emergency repairs.

How quickly can I expect a technician for an emergency commercial ice maker repair near me?

When your ice machine goes down, time is money. That’s why many professional commercial ice maker repair near me companies, including us, offer same-day or 24/7 emergency service. Our goal is always to respond as quickly as possible to minimize your business’s downtime. While specific response times can vary based on your exact location in Columbus or Central Ohio and our current service schedule, it’s crucial to confirm the expected arrival time when you first call. We understand the urgency and strive to get a technician to your location promptly.

Can I perform any basic troubleshooting myself before calling for a repair?

Absolutely! Before you call for professional commercial ice maker repair near me, there are a few simple checks you can perform that might resolve minor issues or help diagnose the problem:

- Check power: Ensure the unit is securely plugged in and that the circuit breaker hasn’t tripped.

- Water supply: Verify that the water supply valve to the ice machine is fully open.

- Air filters: Inspect the air filters and clean them if they are dirty or clogged. This can often resolve issues with low ice production or overheating.

- Clear obstructions: Make sure there’s nothing blocking the ice chute or the ice bin’s sensor.

However, for any internal issues, strange noises, water leaks that don’t stop after basic checks, or if the unit is failing to produce ice despite these steps, it is always safest to call a qualified technician. Attempting complex repairs without proper training can cause further damage or pose safety risks.

Your Partner in Commercial Refrigeration

A broken ice machine can bring your business to a halt, impacting customer satisfaction and your revenue. Promptly addressing warning signs and investing in preventative maintenance are key to avoiding costly disruptions. Choosing a qualified, reliable repair service ensures your equipment is fixed correctly and efficiently, keeping your operations smooth.

At Ohio Heating, we provide expert technicians to keep your commercial refrigeration systems, including your vital ice machines, running smoothly across Columbus and Central Ohio. We understand the critical role ice plays in your business and are committed to delivering timely, professional commercial ice maker repair near me and maintenance services. For comprehensive service you can trust, contact our team today. Learn more about our Commercial Ice Machine Sales and Repair.