Commercial AC Installation: Optimal 2025

Why Warehouse Climate Control Matters for Your Business

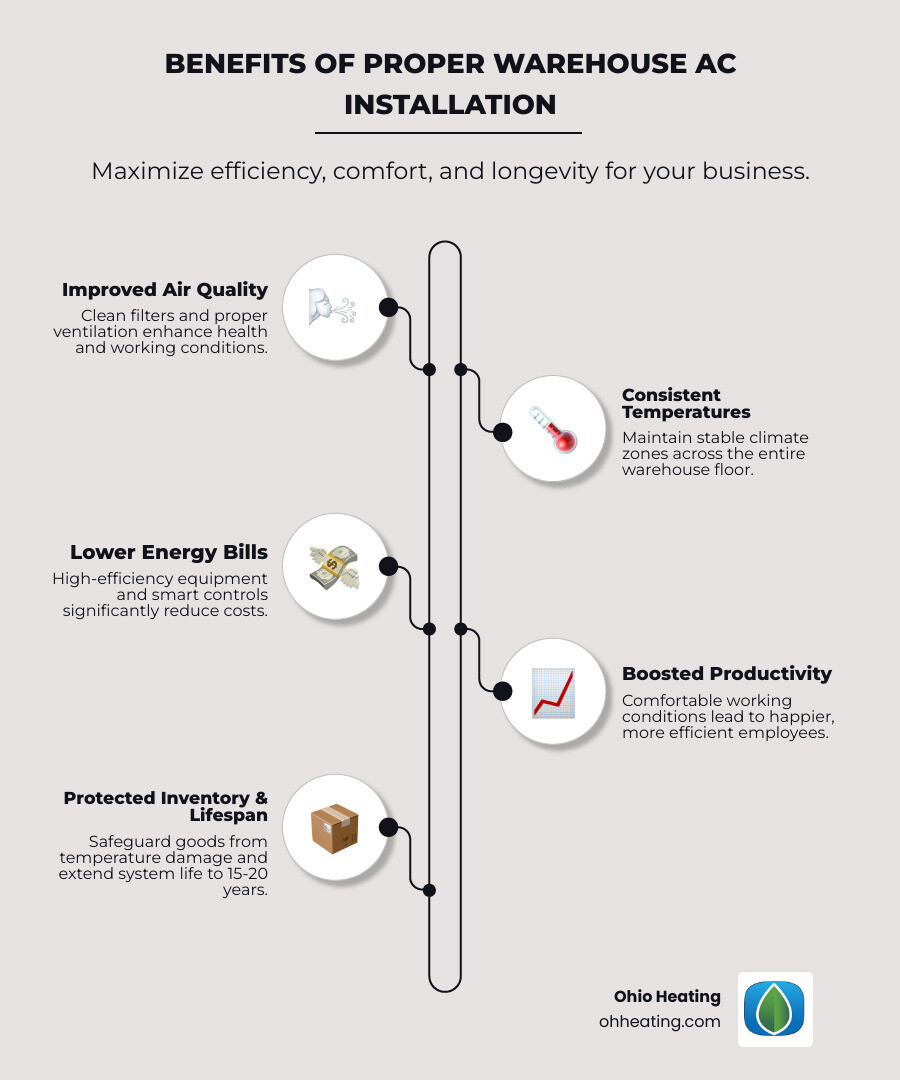

A proper Commercial AC installation in a warehouse directly impacts your bottom line through employee productivity, inventory protection, and operational costs. A well-maintained commercial HVAC system can last 15-20 years, and preventative maintenance can lower energy costs by up to 40 percent.

Key considerations for your project include:

- System Selection: Choose from Rooftop Units (RTUs), Split Systems, or Variable Refrigerant Flow (VRF) systems.

- Professional Installation: Work with NATE-certified technicians who follow all codes and standards.

- Cost Planning: Expect costs of $7.50-$10.50 per square foot, with projects starting at $15,000.

- Installation Timeline: Most warehouse installations take 2-5 days.

- Energy Efficiency: ENERGY STAR certified equipment can reduce energy costs by up to 30%.

Commercial systems are more complex and powerful than residential units, designed to handle high ceilings, large open spaces, and loading docks. The wrong system or poor installation leads to uneven cooling, high energy bills, and frequent breakdowns. Studies show that just 0.042 inches of dirt on condensing coils can reduce cooling efficiency by 21%, proving that professional installation and maintenance are critical.

This guide covers selecting the right system, understanding the installation process, budgeting, and maintaining your investment.

Choosing the Right HVAC System for Your Warehouse

Your warehouse needs more than a home AC unit. Commercial AC installation requires equipment designed for high ceilings, wide-open floor plans, and frequently open loading docks. These factors are the difference between an efficient workspace and one that wastes energy.

At Ohio Heating, our Commercial HVAC Services in Columbus, Ohio are built around matching your specific needs with the right equipment. Here’s how common commercial systems compare:

| System Type | Initial Cost (relative) | Operating Efficiency | Maintenance Needs | Best Use Case for Warehouse |

|---|---|---|---|---|

| Rooftop Packaged Units | Medium | Good | Moderate | Most common for large, open warehouses; all-in-one heating and cooling. |

| Split Systems | Low-Medium | Good | Moderate | Smaller sections or office areas within a warehouse. |

| Variable Refrigerant Flow | High | Excellent | Complex | Large warehouses with varied temperature zones needing precise control. |

Types of Commercial AC Systems

Rooftop Packaged Units (RTUs) are the most popular choice for warehouses. The entire unit sits on the roof, saving floor space and keeping noise outside. They are reliable and straightforward to install, often using economizers for “free cooling” with outside air. While they require ductwork, they are workhorses for large, open spaces.

Single-Split and Multi-Split Systems work like residential ACs, connecting one or more indoor units to an outdoor unit. They are cost-effective for smaller, isolated spaces like offices or break rooms but lack the capacity to cool an entire warehouse floor. Multi-split systems offer some zoning flexibility for distinct areas.

Variable Refrigerant Flow (VRF) Systems are the high-tech, high-efficiency option. These ductless systems can heat and cool different zones simultaneously, making them ideal for facilities with diverse needs like cold storage and offices. They offer significant energy savings (up to 30 percent more efficient than ducted systems) but come with higher upfront costs and require specialized maintenance. You can learn More about VRF systems for technical details.

Key Factors for Your Warehouse Commercial AC Installation

Proper system sizing starts with a detailed load calculation. This analysis determines your exact heating and cooling needs based on:

- Building Size & Ceiling Height: Larger volumes of air require more capacity.

- Insulation Quality: Poor insulation means your system works harder and wastes energy.

- Windows & Loading Doors: These are major points of heat transfer.

- Occupancy & Equipment: People and machinery generate heat, adding to the cooling load.

- Zoning Requirements: Different areas may need independent temperature control for efficiency.

- Energy Efficiency Goals: Higher SEER and EER ratings mean lower long-term operating costs.

An incorrectly sized system—too large or too small—will waste energy, provide poor comfort, and wear out prematurely. We help you find the right balance for long-term value.

The Step-by-Step Commercial AC Installation Process for Warehouses

Getting a Commercial AC installation done right in a warehouse is a carefully planned process. Most warehouse installations take between 2 and 5 days, depending on system size, building complexity, and ductwork requirements. We understand your business can’t stop, so we work with you to schedule the installation to minimize disruption, offering after-hours and weekend work when needed. Our project management approach ensures you have a dedicated point of contact and are kept informed at every stage.

From Planning to Power-On

Our process ensures a successful installation from start to finish:

- Initial Consultation & Site Assessment: We thoroughly evaluate your building’s structure, infrastructure, and unique challenges to understand your budget and energy goals.

- System Design & Load Calculation: Our engineers design a custom solution and perform precise load calculations to determine the exact heating and cooling capacity you need.

- Equipment Selection: We recommend the right equipment from top manufacturers, prioritizing ENERGY STAR certified models to lower your long-term energy costs.

- Site Preparation: We secure work areas, ensure utilities are ready, and make any necessary building modifications. For information on ductwork, see our guide on Ductwork Installation in Columbus, OH.

- Unit Installation & Placement: Our certified technicians install all indoor and outdoor units according to manufacturer guidelines and safety protocols, using cranes for rooftop units when necessary.

- Electrical & Refrigerant Line Connection: All electrical work is done to code, and refrigerant lines are connected following strict EPA guidelines by licensed professionals.

- System Testing & Commissioning: We verify that every component works as designed, checking for leaks, correct refrigerant levels, and optimal performance to ensure efficiency and validate your warranty.

- Final Inspection & Walkthrough: We confirm everything meets local codes and our high standards, then walk you through your new system’s operation and maintenance needs.

Why Professional Installation is Non-Negotiable

Cutting corners on installation is a costly mistake. Professional, licensed technicians are essential for:

- Safety: We follow strict protocols when handling heavy equipment, high-voltage electricity, and refrigerants.

- Code Compliance: Our work meets all local Columbus building codes, preventing fines and ensuring your building’s value and insurance coverage.

- Expertise: Our NATE-certified technicians have the training to install complex commercial systems correctly the first time.

- Warranty Protection: Improper installation can void your manufacturer’s warranty, leaving you to pay for repairs out-of-pocket.

- Refrigerant Handling: We adhere to EPA standards, which prohibit venting refrigerants.

- Electrical Safety: We ensure proper overcurrent protection for equipment safety to prevent fires and equipment damage.

Budgeting for Your Warehouse HVAC Project

Investing in a new Commercial AC installation for your warehouse is a big decision, but a properly installed system pays for itself through improved productivity, protected inventory, and lower energy bills. This return on investment (ROI) is critical to your bottom line.

For a detailed breakdown of local costs, see our guide: Understanding Commercial HVAC Installation Costs in Columbus.

Understanding the Cost of Commercial AC Installation

While a residential system might cost $3,000-$7,000, commercial projects typically start around $15,000 and can exceed $50,000. This reflects the higher capacity and complexity required. A common benchmark for larger spaces is $7.50 to $10.50 per square foot.

Key factors that influence the total project cost include:

- Equipment Costs: The type of system (RTU vs. VRF) and its efficiency rating are major drivers.

- Labor Rates: NATE-certified commercial technicians have specialized skills that are reflected in labor costs.

- System Complexity: A multi-zone system costs more than a simple single-zone setup.

- Ductwork: New or modified ductwork adds to the project cost. Our team handles Ductwork Installation in Columbus, OH as needed.

- Permits & Inspections: We handle all required permitting and coordination.

Achieving Long-Term Cost Efficiency

The initial price is only part of the total cost of ownership. Smart planning can significantly reduce your expenses over the system’s lifespan.

- Rebates & Incentives: We help you identify federal and local rebates for energy-efficient upgrades, which can significantly lower your upfront cost.

- ENERGY STAR Equipment: Certified systems can cut energy costs by up to 30% compared to standard models, often paying for the higher initial investment within a few years.

- Smart Thermostats: Programmable commercial thermostats optimize temperatures based on schedules and occupancy, saving 5% to 20% on energy bills.

- Lifecycle Cost Analysis: We help you evaluate the total cost of ownership—including purchase, installation, energy use, and maintenance—to find the most economical long-term solution.

- Preventative Maintenance: Regular maintenance is proven to lower energy costs by 5% to 40%, extend system lifespan, and prevent expensive emergency repairs. Our Energy Management solutions can further optimize efficiency.

Post-Installation: Maintenance and Troubleshooting

Your new Commercial AC installation is a significant asset that needs regular care to perform reliably for its expected 15 to 20 year lifespan. Like a new vehicle, preventative maintenance is key to ensuring peak efficiency and preventing costly breakdowns.

Businesses that invest in regular maintenance enjoy lower energy bills, fewer service calls, and longer-lasting systems. Learn more about The Importance of Regular HVAC Maintenance for Homes and Businesses.

Essential Maintenance for System Longevity

Key maintenance tasks include:

- Filter Changes: In a dusty warehouse, filters need frequent attention. Check them monthly and replace as needed to prevent restricted airflow and high energy use.

- Coil Cleaning: A thin layer of dirt (0.042 inches) on coils can reduce cooling efficiency by 21%. Professional cleaning restores performance.

- Drain Line Clearing: Clogged drain lines can cause water damage and system shutdowns. We ensure they are clear and flowing freely.

- Belt and Motor Inspection: We check for wear and tear on belts and motors to prevent failures that can shut down your system.

We recommend quarterly professional inspections for most commercial systems. During these visits, we check refrigerant levels, electrical connections, and controls to ensure everything is operating safely and efficiently. Our Commercial HVAC Maintenance Services are designed to fit your business’s schedule.

Common Warehouse HVAC Problems and Solutions

Even well-maintained systems can have issues. Here are common problems to watch for:

- Uneven Heating and Cooling: Often caused by improper system sizing, poor ductwork design, or malfunctioning zoning controls.

- High Energy Consumption: Can indicate dirty coils or filters, refrigerant leaks, or an improperly sized system.

- Malfunctioning Economizers: These “free cooling” devices often fail without regular checks. A study found nearly 66% were not working correctly, wasting significant energy.

- Refrigerant Leaks: Reduced cooling, ice on coils, or hissing sounds can signal a leak. Our EPA-certified technicians can find and repair them safely.

- Strange Noises: Squealing, rattling, or banging sounds indicate mechanical problems that need immediate attention to prevent major failures. For more, see our guide on Common Issues Causing Commercial HVAC System Failures.

Frequently Asked Questions about Warehouse AC Installation

We’ve been installing commercial HVAC systems in Columbus warehouses since 1999. Here are answers to the most common questions we hear.

How long does a typical warehouse AC installation take?

Most Commercial AC installation projects for warehouses take between 2 and 5 days. The exact timeline depends on factors like the system’s size and complexity, the building’s layout, and whether new ductwork is needed. We work closely with you to schedule the installation to minimize disruption to your operations, including evening or weekend work if necessary.

How is the right size HVAC system determined for a warehouse?

We determine the right size through a detailed Manual J load calculation, not guesswork. This scientific analysis accounts for:

- Square footage and ceiling height

- Insulation quality

- Number of windows and loading doors

- Occupancy levels

- Heat-generating equipment (forklifts, machinery, lighting)

An incorrectly sized system will be inefficient and wear out prematurely. A proper load calculation ensures your system is perfectly matched to your space for optimal performance and energy efficiency.

What is the average lifespan of a well-maintained commercial HVAC system?

A properly installed and regularly maintained commercial HVAC system should last between 15 and 20 years. This lifespan is not automatic; it depends on consistent preventative maintenance. Regular tune-ups, filter changes, and coil cleanings are essential to extend your system’s life, maintain efficiency, and avoid costly repairs. Neglecting maintenance can cut the lifespan nearly in half.

Your Partner for Reliable Warehouse Climate Control

Choosing the right system, ensuring professional Commercial AC installation, and committing to regular maintenance are the keys to a reliable and efficient warehouse climate. When done correctly, your HVAC system becomes a critical asset that protects your inventory, keeps your team productive, and controls energy costs.

The unique challenges of a warehouse environment—high ceilings, loading docks, and large open spaces—demand professional expertise. Since 1999, Ohio Heating has helped businesses across the Columbus area achieve comfortable and efficient operations year-round.

If you’re ready to create a better environment in your warehouse, our team is here to help. We provide comprehensive Commercial HVAC solutions custom to the specific needs of Columbus-area warehouses. Let’s partner to build a comfortable, efficient, and productive space that serves your business for years to come.