Boiler heat exchanger: The Ultimate 101 Guide

The Heart of Your Home’s Heating System

A boiler heat exchanger is the crucial component that transfers heat from burning fuel to the water circulating through your heating system. It’s the “heart” of your boiler, providing warmth and hot water to your building.

Quick Answer for Property Managers:

- Primary Function: Transfers heat from combustion gases to water without the two fluids mixing

- Location: Core component inside every boiler system

- Lifespan: Typically 15-20 years with proper maintenance

- Cost to Replace: $300-$500 for parts, plus labor (often close to new boiler cost)

- Efficiency Impact: Condensing models with advanced exchangers reach 99% efficiency vs. 78% for older single-exchanger units

- Maintenance Need: Annual professional inspection to prevent limescale buildup, corrosion, and sludge blockages

When a boiler stops producing heat, the heat exchanger is often the culprit. This component determines your system’s efficiency, energy bills, and whether your tenants stay comfortable during Ohio’s harsh winters.

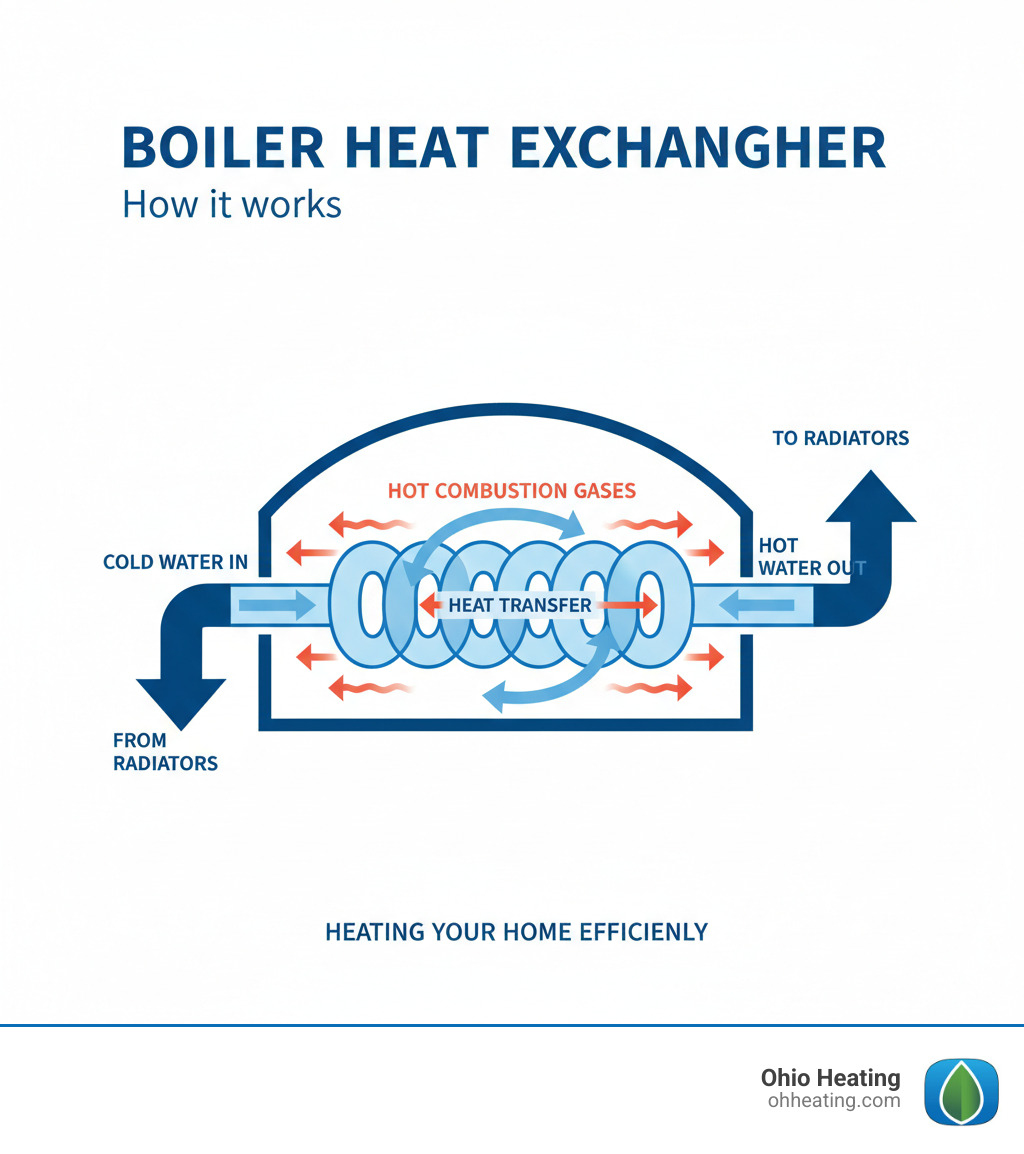

The heat exchanger works by passing hot combustion gases from the burner over a coiled pipe containing water. Heat transfers through the metal walls, warming the water without the two substances ever mixing. This heated water then circulates through radiators or baseboard heaters to warm your property.

For property managers, understanding this component is critical. A failing heat exchanger means emergency calls, potential water damage, and unexpected capital expenses. Regular maintenance can prevent thousands in emergency repairs and keep your heating system running at peak efficiency.

What is a Boiler Heat Exchanger and How Does It Work?

Your boiler heat exchanger is a metal component that transfers heat from burning fuel to the water in your heating system without letting them mix, ensuring safe and effective operation.

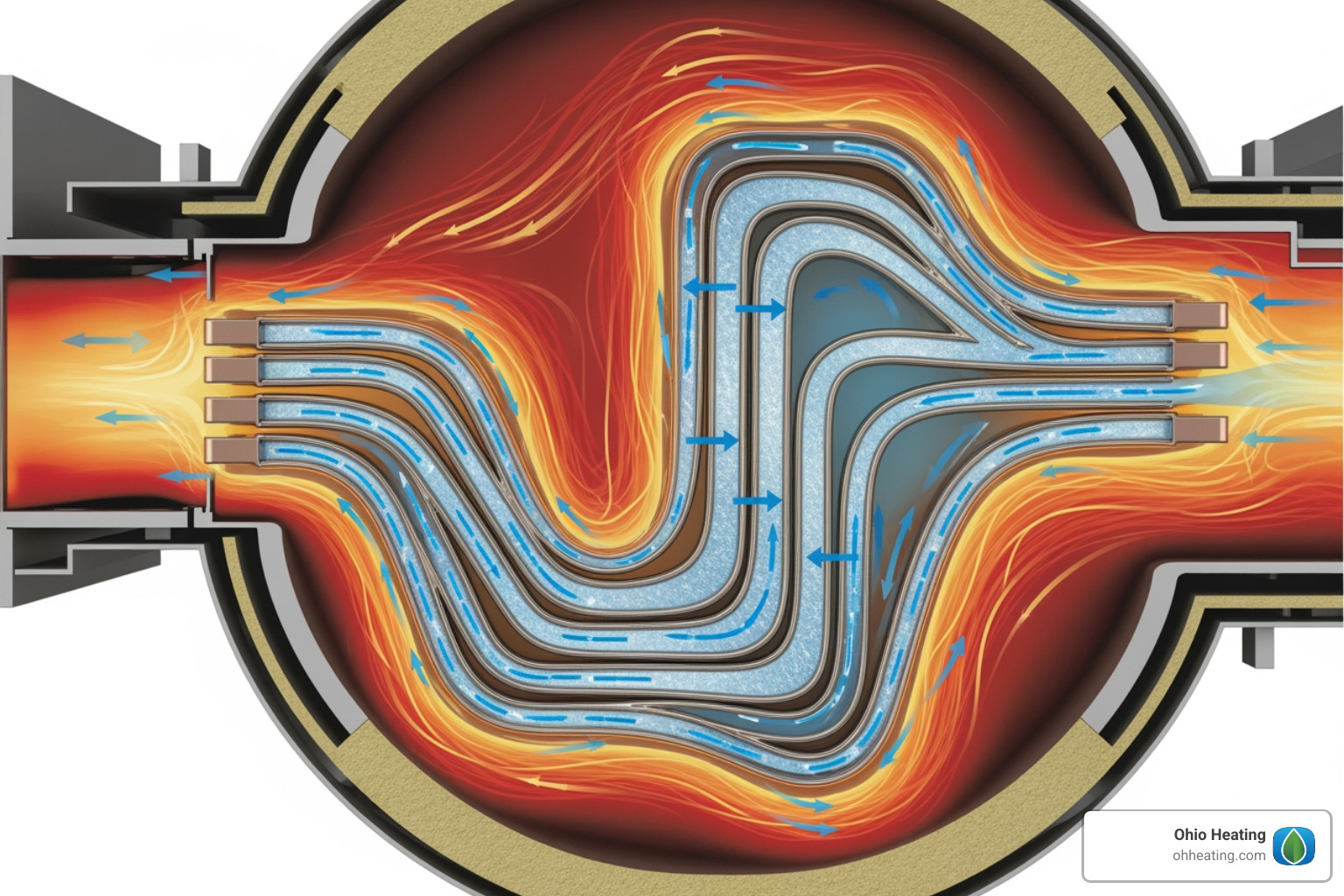

When your boiler runs, fuel burns to create hot flue gases. These gases flow over a series of metal pipes or plates containing circulating water. The heat radiates through the metal walls, warming the water inside.

This heated water then flows through your central heating circuit to warm radiators or baseboard heaters. In a combi boiler, common in many Columbus homes, the boiler heat exchanger also provides instant domestic hot water.

The design, often a coiled pipe, maximizes the surface area for heat transfer, increasing efficiency and reducing wasted energy.

Combi boilers often use two exchangers: a primary one for central heating and a smaller, secondary plate-style unit for domestic hot water. When you turn on a tap, heated water is diverted through the secondary exchanger to provide hot water on demand without a storage tank.

This system operates in a continuous loop: cold water enters, is heated, circulates to radiators or taps, cools, and returns to be reheated. The efficiency of this process directly impacts your energy bills. A clean heat exchanger transfers heat quickly, while a clogged one forces the boiler to work harder and burn more fuel.

Types, Materials, and Their Impact on Boiler Efficiency

The design and material of a boiler heat exchanger directly impact your boiler’s performance, lifespan, and energy costs. Understanding the differences matters for your home or business in Columbus, OH.

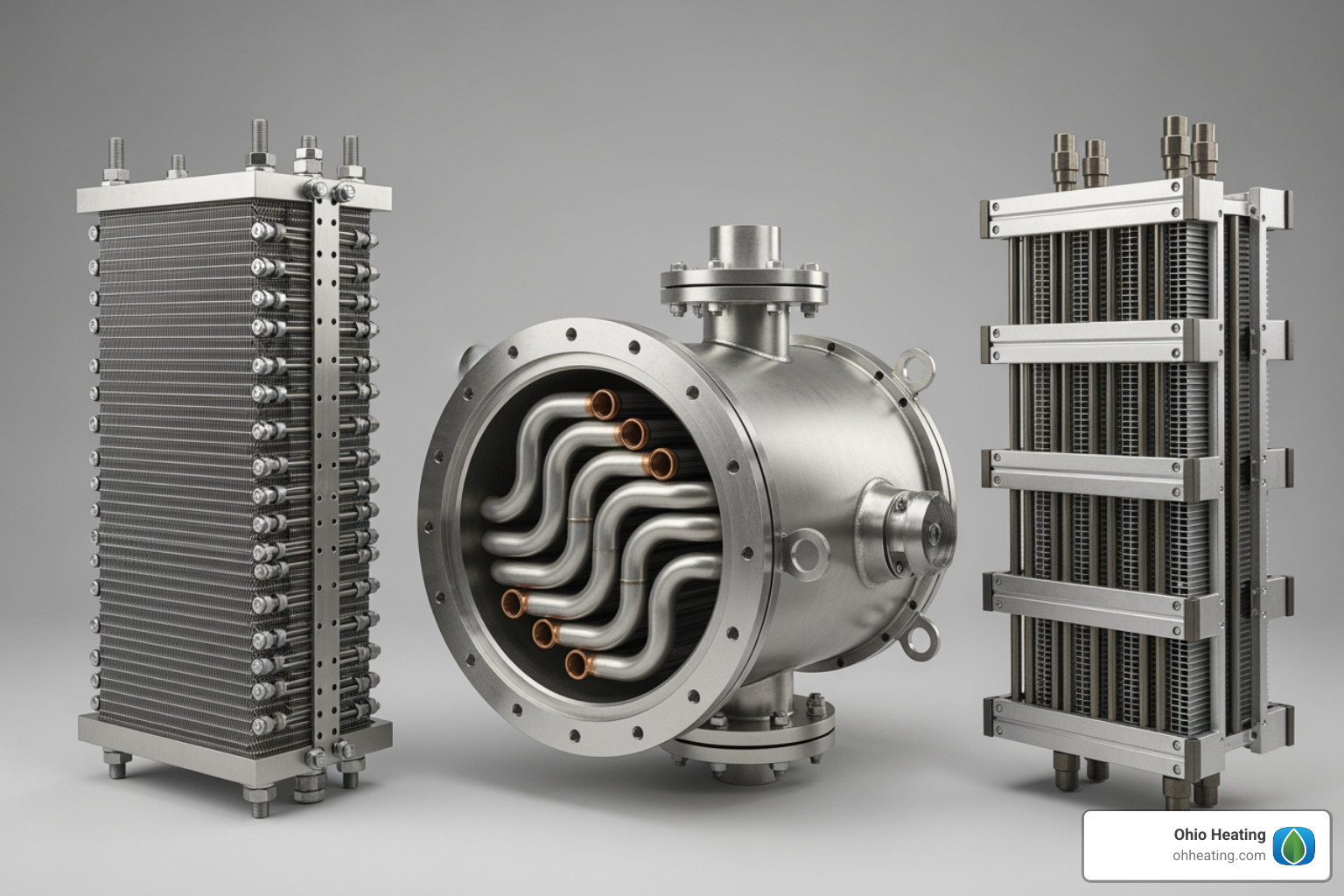

Common Heat Exchanger Designs

- Mono-thermal systems use separate exchangers for central heating and domestic hot water.

- Bi-thermal systems use a single, compact heat exchanger for both heating and hot water, with separate internal channels.

- Plate heat exchangers, common in combi boilers, use stacked metal plates to provide instant hot water efficiently.

- Water-to-air heat exchangers transfer heat from hot water to air, warming spaces like garages.

- Water-to-water heat exchangers transfer heat between two separate water streams, essential for radiant floor heating or separating boiler water from potable water.

Key Materials: Stainless Steel vs. Aluminum

The material choice affects durability and cost.

- Stainless steel offers superior corrosion resistance and a long lifespan (15-20 years). While more expensive upfront, it pays off in reliability.

- Aluminum is lightweight, cost-effective, and has high thermal conductivity for efficient heat transfer. However, it can be more susceptible to corrosion, making proper maintenance crucial.

Efficiency Showdown: Condensing vs. Non-Condensing Boilers

The heat exchanger is key to boiler efficiency.

- Non-condensing boilers use a single heat exchanger and vent hot flue gases, wasting significant energy. This limits their efficiency to around 78% and gives them a higher carbon footprint.

- Condensing boilers use a larger or secondary heat exchanger to capture additional heat from flue gases. They cool the gases until water vapor condenses, releasing “latent heat.” This process boosts efficiency to as high as 99%, leading to lower energy bills and a smaller environmental impact, making them the modern standard.

Diagnosing and Maintaining Your Boiler Heat Exchanger

Without proper care, even a robust boiler heat exchanger can fail. Recognizing warning signs and performing regular maintenance can prevent costly breakdowns for property managers and homeowners in Columbus.

Symptoms of a Faulty Boiler Heat Exchanger

Be alert for these signals of a failing boiler heat exchanger:

- Unusual noises: High-pitched whistling (kettling) suggests limescale buildup, while tapping or knocking often indicates sludge.

- Water leakage from the boiler: Dripping from the boiler casing can mean the heat exchanger is cracked or corroded.

- Boiler lockout: The system may shut down to protect itself from overheating caused by a clog.

- Poor performance: If the radiators remain cold or hot water is lukewarm, the exchanger may not be transferring heat effectively.

Common Causes of Failure and Inefficiency

Several issues can damage a boiler heat exchanger:

- Limescale buildup: Common in Central Ohio’s hard water, mineral deposits act as an insulator, reducing efficiency and causing overheating that can lead to cracks.

- Central heating sludge: A mix of rust and debris that settles in the exchanger, creating blockages and restricting water flow.

- Corrosion: The constant exposure to water and temperature changes can eat away at the metal, causing leaks and cracks.

- Cracks and physical damage: Thermal stress and material fatigue over 15-20 years can cause cracks, which typically require replacement.

Professional Cleaning and Maintenance for your Boiler Heat Exchanger

Most heat exchanger problems are preventable with professional maintenance. This is not a DIY job, as it can void warranties and create safety hazards.

- Annual servicing: A certified technician should inspect your boiler annually to catch early signs of limescale, sludge, or corrosion.

- Chemical flush: Also known as a power flush, this process uses cleaning agents to remove heavy buildup of sludge and scale from the system.

- System filters: A magnetic filter installed in the heating circuit captures rust and debris before it reaches the heat exchanger.

- Limescale reducers: These devices inhibit mineral deposit formation, protecting the exchanger in hard water areas.

boiler maintenance is crucial for protecting your investment and preventing the inconvenience of losing heat. At Ohio Heating, we provide expert boiler service to help Columbus homes and businesses avoid these problems.

Repair vs. Replacement: What’s the Right Choice?

When your boiler heat exchanger fails, you face a choice: repair or replace? The right decision for your Columbus, OH property depends on the boiler’s age, the extent of the damage, and the cost.

The Age Question

If your boiler is over 10-15 years old, investing in a major repair like a heat exchanger replacement may not be cost-effective. An older system that needs one major repair today may need another one tomorrow.

Assessing the Damage

The severity of the problem is a key factor. Minor issues, like small blockages or a worn seal, can often be repaired by a skilled technician. However, significant cracks, extensive corrosion, or severe blockages usually mean the heat exchanger has reached the end of its life and must be replaced.

The Cost Reality

A boiler heat exchanger is one of the most expensive parts in your system. The part alone can cost several hundred to over a thousand dollars. With labor, a full replacement might cost $500 to $1,500 or more. When this cost approaches 50-75% of a new boiler’s price, replacement becomes a serious consideration.

When Repair Makes Sense

If your boiler is less than 10 years old and the problem is minor, repair is usually the smart choice. A targeted fix can provide many more years of reliable service without the cost of a full replacement.

When Replacement is the Better Path

With major damage like a crack or extensive corrosion, replacement is necessary. If your boiler is over 10 years old, consider replacing the entire unit instead of just the heat exchanger. Modern condensing boilers are far more efficient, and the long-term energy savings can offset the initial investment while providing greater reliability.

Our team at Ohio Heating provides honest assessments to help Columbus homeowners and property managers make the right choice for their budget and needs, whether it’s a repair or a full system upgrade.

Frequently Asked Questions about Boiler Heat Exchangers

Here are answers to the most common questions we hear from our Columbus, OH clients about boiler heat exchangers.

How long does a boiler heat exchanger typically last?

A well-maintained boiler heat exchanger should last as long as the boiler itself, typically 15 to 20 years. Regular professional maintenance is key to reaching this lifespan; neglect can lead to premature failure from limescale, sludge, or corrosion.

Can a faulty heat exchanger be repaired?

It depends on the damage. Minor issues like small blockages can often be cleared with a professional chemical flush. However, significant damage such as cracks or severe corrosion almost always requires a full replacement, as repairs are not a safe or effective long-term solution.

What are the most common signs my heat exchanger is failing?

Your boiler will often provide warning signs before a complete failure. The most common symptoms include:

- Strange noises: Whistling (kettling) or banging sounds.

- Water leaks: Any water dripping from the boiler unit.

- Poor performance: Radiators that don’t get hot or lukewarm tap water.

- Lockouts: The boiler repeatedly shutting itself down.

If you notice any of these signs, contact a professional immediately. Early diagnosis can prevent a complete system failure. At Ohio Heating, we have over two decades of experience diagnosing and fixing these issues to keep you comfortable.

Keep Your Home Comfortable with Expert Boiler Service

Your boiler heat exchanger is the heart of your heating system, and its health directly impacts your comfort, energy bills, and your boiler’s lifespan. Neglecting it can lead to limescale, sludge, and corrosion, resulting in a sudden breakdown on the coldest night of the year.

You can avoid this with proactive maintenance. Annual inspections by certified technicians are the best way to prevent expensive surprises. Professionals can spot early warning signs that homeowners might miss, allowing for affordable fixes before they become system-threatening emergencies.

At Ohio Heating, we’ve been keeping Columbus homes and businesses comfortable since 1999. Our team has over two decades of experience navigating Ohio’s weather, and we know boilers inside and out. We specialize in comprehensive installation, repair, and maintenance for all boiler systems, treating every call with the urgency it deserves.

Whether you need routine maintenance to keep your boiler heat exchanger running smoothly, an emergency repair, or guidance on upgrading to a more efficient system, we’re here to help. Don’t wait for a failure during a cold snap. Invest in professional care to ensure your boiler provides years of reliable service.

Contact us for boiler sales and service and let us help you maintain the comfort and warmth your property deserves.