Ice machine condenser cleaning: Ultimate 2025 Guide

Why Ice Machine Condenser Cleaning Matters for Your Business

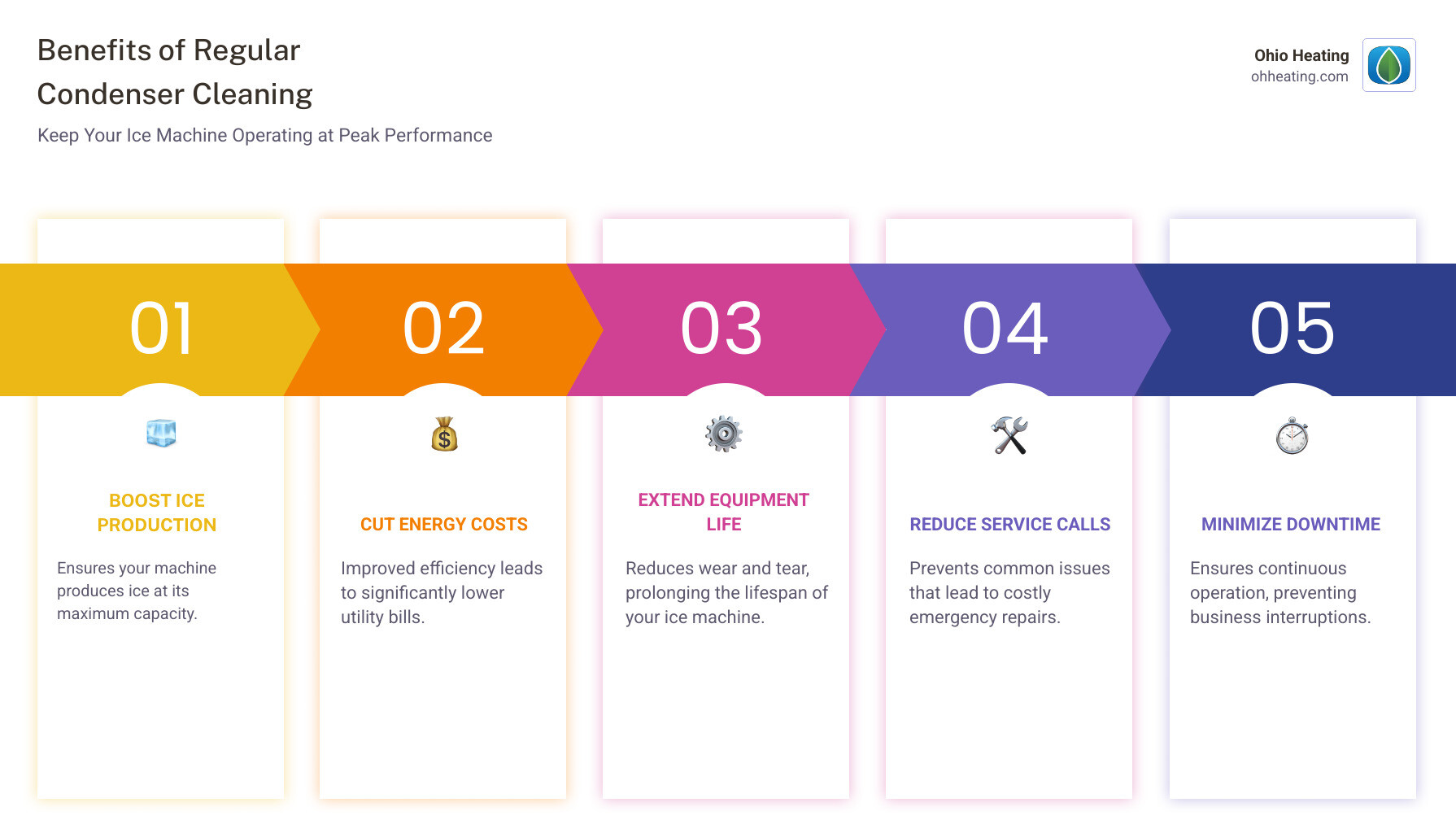

Ice machine condenser cleaning is a critical maintenance task that keeps your equipment running efficiently and prevents costly breakdowns. Here’s what you need to know:

Quick Answer: Ice Machine Condenser Cleaning Essentials

- What to clean: The condenser fins and coils (usually located behind an access panel)

- How often: Every 6 months minimum, more frequently in kitchens, bakeries, or dusty environments

- Basic process: Disconnect power → Remove access panel → Brush/vacuum debris → Apply degreaser if needed → Straighten bent fins → Reassemble

- When to call a pro: Remote condensers, water-cooled systems, or if you’re uncomfortable with disassembly

- Why it matters: Dirty condensers are one of the leading causes of ice equipment service calls and can reduce ice production to little or nothing

A dirty condenser doesn’t just reduce efficiency—it puts your entire ice production at risk. When dust, grease, and debris clog the condenser fins, your ice machine struggles to expel heat. This causes higher operating temperatures, which can lead to component failure, reduced ice capacity, and eventually a complete shutdown during your busiest hours.

The good news? Most air-cooled condenser cleaning is straightforward and can be done in-house with basic tools. For self-contained units, a simple cleaning routine every six months can avoid condenser-related repair costs and keep your ice flowing when you need it most.

I’m Jill Frattini, a Service Coordinator at Ohio Heating with several years of HVAC and refrigeration experience. I’ve coordinated countless ice machine condenser cleaning projects and service calls, and I’ve seen how regular maintenance prevents expensive emergency repairs and keeps businesses running smoothly.

The Heart of the Chill: What is a Condenser and Why is Cleaning Crucial?

Imagine your ice machine’s condenser as the radiator in a car. Just like a car radiator needs to dissipate heat from the engine to prevent overheating, an ice machine condenser must efficiently release heat from the refrigerant to make ice. It’s a vital component in the refrigeration cycle, where the hot, high-pressure refrigerant gas is cooled and condensed back into a high-pressure liquid. This change is essential for the ice-making process to continue.

When the condenser gets dirty, covered in dust, lint, or grease, it can’t perform its job effectively. This leads to a cascade of problems:

- Reduced ice capacity: The machine can’t cool the refrigerant efficiently, meaning less ice is produced, or sometimes, no ice at all.

- Higher operating temperatures: The refrigeration system has to work harder to overcome the heat buildup, leading to higher-than-recommended operating temperatures.

- Component failure: Persistent high temperatures put immense strain on critical components like the compressor, potentially leading to premature failure. This is often an expensive repair.

- Increased energy consumption: A struggling machine draws more power, driving up your utility bills.

- Mechanical damage: The overall stress on the system can cause other mechanical failures or damage, leading to more frequent and costly repairs.

A dirty condenser doesn’t just reduce efficiency—it puts your entire ice production at risk. We’ve seen how neglected condensers can lead to a host of problems. For more insights into what can go wrong, check out our guide on Common ice machine problems: Know the signs.

Signs Your Ice Machine Condenser Needs Cleaning

Your ice machine often gives you clues when its condenser is struggling. Keeping an eye out for these signs can help you prevent a minor issue from becoming a major headache:

- Hot air from vents: While some warm air is normal, excessively hot air or a noticeable increase in ambient temperature around the machine indicates it’s working too hard to dissipate heat.

- Machine runs constantly: If your ice machine seems to be running non-stop but isn’t producing the usual amount of ice, its efficiency is likely compromised by a dirty condenser.

- Low ice production: This is one of the most direct indicators. If your machine is making less ice than usual, or if the ice quality is poor (e.g., smaller, softer cubes), a clogged condenser could be the culprit.

- Poor ice quality: Beyond just quantity, a struggling system can affect the density and consistency of your ice.

- Visible dust or grease: The most obvious sign! If you can see a layer of dust, lint, or greasy film on the condenser coils or fins, it’s definitely time for a clean.

- Unit shuts down unexpectedly: In severe cases, the machine’s safety mechanisms might kick in to prevent critical damage, causing it to shut down. This is a clear warning sign.

The Consequences of a Dirty Condenser

Neglecting your ice machine’s condenser is like ignoring a check engine light in your car – eventually, you’re going to break down. The consequences for your business can be severe:

- Decreased efficiency: The refrigeration system works harder, but produces less. This means your machine is essentially “spinning its wheels” without moving forward.

- Higher utility bills: That extra effort translates directly into increased energy consumption. What could have been a simple cleaning task now costs you more on your monthly energy statement.

- Unnecessary strain on components: The compressor and other parts are constantly under stress, accelerating wear and tear.

- Compressor failure: This is the big one. A dirty condenser is a leading cause of compressor failure, which is often the most expensive component to replace in an ice machine.

- Costly service calls: Dirty air-cooled condensers are, unfortunately, one of the leading causes of ice equipment service calls. These unexpected expenses can quickly eat into your budget.

- Business downtime: If your ice machine breaks down during peak hours, you risk losing sales, disappointing customers, and disrupting your operations. Imagine a restaurant on a hot summer day without ice!

It’s possible to avoid condenser-related repair costs and service fees by ensuring your air-cooled condenser is cleaned regularly. A dirty condenser doesn’t just reduce efficiency—it puts your entire soft serve or frozen beverage operation at risk. For more on how we help businesses in Columbus, Ohio, with their refrigeration needs, visit our More on refrigeration issues.

Know Your Type: Air-Cooled, Water-Cooled, and Remote Condensers

Not all ice machine condensers are created equal. Understanding the different types is crucial because it dictates how (or if) you should clean them yourself. Here’s a breakdown of the three main types:

| Criteria | Air-Cooled Condenser | Water-Cooled Condenser | Remote Condenser |

|---|---|---|---|

| Location | Self-contained within the ice machine | Self-contained within the ice machine | Separated from the ice machine (often on a rooftop) |

| Cooling Method | Uses ambient air blown over fins by a fan | Uses a continuous flow of water to cool refrigerant | Uses ambient air, but located remotely |

| Cleaning Needs | Requires regular cleaning (dust, lint, grease) | Wiped during basic maintenance, no air-side cleaning | Requires professional cleaning (often difficult access) |

| Pros | More energy-efficient, less water usage | Quieter, consistent performance in hot environments | Reduces heat/noise inside, good for hot kitchens |

| Cons | Sensitive to ambient air temperature and cleanliness | Uses significant water (approx. 5x air-cooled), water disposal | Complex installation, professional maintenance only |

| DIY Cleaning? | YES, for self-contained units | NO (no external fins to clean) | NO (requires specialized equipment and access) |

1. Air-Cooled Condensers: These are the most common type, especially for self-contained ice machines. They work by drawing in ambient air and blowing it over a series of copper tubes and aluminum fins, which contain the hot refrigerant. The heat is transferred to the air and expelled.

- Pros: Generally more energy-efficient and use significantly less water than water-cooled units. Most air-cooled machines qualify for the ENERGY STAR program.

- Cons: Their efficiency is highly dependent on good ventilation and clean ambient air. They put out more heat (BTUs) into the immediate environment.

- Cleaning: These are the condensers we’ll focus on for DIY cleaning, as they are prone to collecting airborne dust, lint, and grease.

2. Water-Cooled Condensers: These condensers use a continuous flow of cold water to cool the refrigerant. They are a shell-and-tube design where refrigerant flows through tubes that are surrounded by a jacket of circulating water.

- Pros: Excellent performance in hot, poorly ventilated environments, and they operate very quietly.

- Cons: They use a substantial amount of water, roughly five times more than air-cooled condensers. This can be a concern in areas with water restrictions or high utility costs. Water disposal is also a factor.

- Cleaning: There’s no external “fin” cleaning needed for water-cooled condensers in the same way as air-cooled units. They are typically wiped out during basic ice machine maintenance.

3. Remote Condensers: These are air-cooled condensers, but instead of being integrated into the ice machine unit, they are located separately, often on a rooftop or in a different mechanical space. The ice machine unit itself only contains the evaporator and other ice-making components.

- Pros: They keep heat and noise away from the ice production area, which is ideal for small, hot kitchens or environments where quiet operation is paramount.

- Cons: Installation is more complex, requiring refrigerant lines to be run between the ice machine and the remote condenser.

- Cleaning: Remote condensers are NOT suitable for DIY cleaning. Due to their location and the specialized equipment needed to access and service them, these always require a professional ice machine technician.

For businesses in Columbus, Central Ohio, or anywhere in Ohio, understanding your condenser type is the first step to proper maintenance. If you have an air-cooled unit, you’re in luck – much of the cleaning can be handled in-house!

The Ultimate Guide to Air-Cooled Ice Machine Condenser Cleaning

This section is dedicated to empowering you to tackle ice machine condenser cleaning for your self-contained air-cooled units. These are the most common type and, thankfully, often suitable for DIY cleaning. Regular cleaning is a simple, proactive step that can save you significant repair costs and keep your ice machine humming happily.

Gearing Up: Essential Tools and Solutions for Condenser Cleaning

Before you dive in, gather your arsenal. Having the right tools makes the job safer, easier, and more effective.

- Soft bristle brush or wire welding brush: Ideal for gently dislodging dust and lint from the condenser fins. Make sure it’s soft enough not to damage the delicate aluminum fins.

- Fin comb: If you notice any bent or smashed fins, a fin comb can carefully straighten them, restoring proper airflow.

- Vacuum cleaner with a brush attachment: Excellent for removing loose debris and dust without scattering it.

- Screwdriver set: You’ll likely need this to remove access panels.

- Flashlight: To help you see into tight spaces and ensure you’ve cleaned thoroughly.

- Gloves: Liquid-proof gloves are essential, especially if you’re using cleaning solutions.

- Safety glasses: Protect your eyes from dislodged debris or chemical splashes.

- Commercial condenser coil cleaner (degreaser): For units in greasy environments (like kitchens), a specific degreaser is necessary. Ensure it’s approved for use on refrigeration coils. Do not use general coil cleaners or oven cleaners, as they can be too harsh.

- Nickel-safe cleaners: If you’re also performing an internal cleaning cycle on your machine, always use nickel-safe cleaners as recommended by your ice machine’s manufacturer.

A Step-by-Step Guide to DIY Ice Machine Condenser Cleaning

Here’s how to carefully clean your self-contained air-cooled ice machine condenser:

- Safety First: Disconnect Power: This is non-negotiable. Always unplug the ice maker or disconnect its power at the circuit breaker. We want you to stay safe!

- Access the Condenser: Locate and remove the lower access panel, usually held by a few screws. You might need to pull the bottom forward and then down to fully remove it.

-

Initial Debris Removal (Dry Cleaning):

- Using your vacuum cleaner with a brush attachment, thoroughly remove dirt, lint, and dust from the condenser fins and the unit compartment.

- For stubborn matted material, gently scrub with your soft bristle brush. Remember to brush with the condenser fins, not against them, to avoid bending them.

-

Straighten Bent Fins (If Necessary): Carefully use a fin comb to straighten any bent or smashed fins. This restores optimal airflow.

- Tackling Greasy Buildup: If your ice machine is in a kitchen or environment with airborne grease, dry cleaning won’t be enough.

- Apply a commercial condenser coil cleaner (degreaser) specifically designed for this purpose. Follow the product instructions for application and soaking time.

- Gently brush the fins again, still brushing with the fins, to help loosen the grease.

- Rinse thoroughly. Some degreasers can be rinsed with a gentle water spray from the entering air side, ensuring the water drains away properly. Repeat until all grease is gone.

- Important: Never use oxygen to blow out an air-cooled condenser, as it is explosive and dangerous.

- Reassembly: Once the condenser is clean and dry, replace the access panel, securing it with the screws.

- Power On: Plug the ice maker back in or reconnect the power.

It may take up to 24 hours for temperatures to return to normal operation after condenser cleaning, so don’t fret if it doesn’t immediately start making ice at full capacity.

How Often Should You Clean Your Condenser?

The frequency of ice machine condenser cleaning depends heavily on your environment. Think of it like changing your car’s air filter – more dust means more frequent changes.

- Baseline Frequency: For most commercial ice machines, we recommend cleaning the condenser every 6 months. Some manufacturers, like Ice-O-Matic, suggest cleaning and sanitizing every 6 months, but no more than once per month. Scotsman also recommends semi-annual cleaning for condenser fins.

- Environmental Factors: This is where it gets tricky for businesses in Central Ohio or Columbus.

- High-grease kitchens: If your ice machine is near fryers or cooking equipment, airborne grease will quickly clog the condenser. You might need to clean it as often as once a month, or even weekly in very busy, greasy environments.

- Bakeries (airborne yeast): Similar to grease, airborne yeast can accumulate rapidly on condenser fins, requiring more frequent cleaning.

- Dusty areas: Any environment with a lot of dust, lint, or sawdust will necessitate more frequent cleaning.

- Clean office environments: In a relatively clean office setting, biannual cleaning may suffice.

We recommend cleaning the condenser each time you run a cleaning cycle for the ice-making system. Even if it looks clean from the outside, dust and debris can accumulate deep within the fins. Always refer to your ice machine’s specific manufacturer guidelines. For an example of a detailed maintenance schedule, you can View an example maintenance schedule.

When to Call in the Professionals

While many air-cooled condensers can be cleaned in-house, there are definitely times when it’s best to call in the cavalry – or, in our case, the HVAC and refrigeration experts at Ohio Heating. Knowing when to step back can save you time, prevent damage, and ensure the job is done right.

Here’s when we recommend you reach out to us:

- Remote Condensers: As discussed, if your ice machine has a remote air-cooled condenser (often located on a rooftop), it requires specialized equipment and expertise to access and clean safely. This is definitely a job for a professional ice machine technician.

- Water-Cooled Condensers: While they don’t have external fins that get dusty, water-cooled systems require different maintenance, often related to water quality and internal scaling, which is beyond basic DIY.

- Complex Disassembly: Some commercial ice machines require significant disassembly to access the condenser, potentially involving fan assemblies, electrical components, or tricky panels. If you’re unsure how to proceed without risking damage, it’s safer to call us.

- Electrical Components: If the condenser is in close proximity to sensitive electrical wiring or components that you’re not comfortable working around, leave it to the experts.

- Stubborn Grease or Build-up: If you’ve attempted a cleaning and the condenser is still heavily clogged with grease or a stubborn, caked-on residue, our professional-grade cleaners and pressure washing equipment can often do what a DIY approach cannot.

- Significant Fin Damage: If the condenser fins are severely bent, corroded, or damaged, simply cleaning them won’t restore efficiency. They may need to be professionally straightened or, in extreme cases, the coil replaced.

- If You’re Unsure: When in doubt, call us! It’s always better to be safe than sorry. An incorrect cleaning attempt can damage your machine and void its warranty. Many manufacturers, like Ice-O-Matic, recommend that cleaning be done by a trained technician.

For businesses in Columbus and Central Ohio, our team at Ohio Heating is equipped to handle all types of Professional refrigeration services. We’re experts at Identifying ice machine repair challenges in Columbus and ensuring your equipment runs smoothly.

Frequently Asked Questions about Condenser Maintenance

Can I use a pressure washer or harsh chemicals on my condenser?

No, absolutely not. Using a high-pressure washer on your condenser can easily bend or damage the delicate aluminum fins, which are crucial for heat exchange. Once bent, these fins restrict airflow, making your machine less efficient than before.

Similarly, harsh chemicals like strong acids (Nitric, Sulfuric, Hydrochloric, Carbolic, Acetic), non-food-grade vinegar (with high acetic acid concentration), or any chlorine-based solutions (like bleach) should never be used. These can cause corrosion, flaking, and severe damage to the evaporator and other metal components of your ice machine. Always use a gentle stream of water for rinsing and only manufacturer-approved, nickel-safe commercial condenser coil cleaners.

Does condenser cleaning differ much between brands?

The basic principles of ice machine condenser cleaning remain the same across brands: you need to remove debris to restore airflow. However, the specifics can certainly differ. Access panels, component layout, and the type of condenser (air-cooled, water-cooled, remote) can vary greatly between manufacturers like KitchenAid, Sub-Zero, Hoshizaki, Scotsman, and Ice-O-Matic.

For instance, a KitchenAid ice maker might have a different panel removal process than a commercial Scotsman unit. Always consult your owner’s manual for specific instructions regarding your model. This will ensure you’re accessing the condenser correctly and using any recommended brand-specific tools or cleaners. If you need to find product literature for your appliance, you can often Find product literature for your appliance here.

What if my ice machine still isn’t working properly after cleaning the condenser?

A dirty condenser is a very common issue, but it’s not the only problem that can plague an ice machine. If you’ve carefully cleaned your condenser and your machine still isn’t performing as it should, it’s a strong indication that another issue is at play. This could include:

- Low refrigerant: A leak in the refrigeration system can lead to insufficient cooling.

- Failing compressor: If the compressor is weak or failing, it won’t be able to properly circulate the refrigerant.

- Issues with other components: Problems with the water inlet valve, evaporator, control board, or sensors can also disrupt ice production.

In such cases, professional diagnosis is essential. Our technicians at Ohio Heating have the tools and expertise to identify the root cause of the problem and provide effective solutions for all your business appliances.

Keep Your Ice Machine Running Smoothly

Regular ice machine condenser cleaning is not just a chore; it’s an investment in the longevity and efficiency of your equipment. By performing this essential maintenance, you ensure peak performance, prevent unexpected breakdowns, and keep your operating costs down. Think of it as a small effort that yields big returns for your business in Columbus, Central Ohio, and throughout the state.

At Ohio Heating, we understand that your ice machine is a critical asset. Our team is dedicated to ensuring your comfort and operational reliability, helping you prevent issues like extreme temperatures and costly downtime. For expert service, professional ice machine condenser cleaning, and to explore options for your business, learn more about our commercial ice machine sales and repairs. We’re here to help you keep your cool!