Data center HVAC maintenance: 66% Reliable Uptime

Why Your Data Center’s Lifespan Depends on HVAC Maintenance

Data center HVAC maintenance is the scheduled inspection, cleaning, and repair of cooling systems that keep servers and IT equipment running at safe temperatures. Without it, even the most advanced data center faces overheating, equipment failure, and costly downtime.

Key maintenance practices include:

- Regular filter changes – Every 1-3 months to maintain airflow

- Coil cleaning – Prevents efficiency loss of up to 39% on dirty systems

- Refrigerant level checks – Ensures optimal cooling capacity

- Temperature and humidity monitoring – Keeps conditions within ASHRAE’s recommended 64-81°F range

- Preventive inspections – Reduces unplanned outages by up to 66%

- Condensate drain flushing – Prevents water damage and system failures

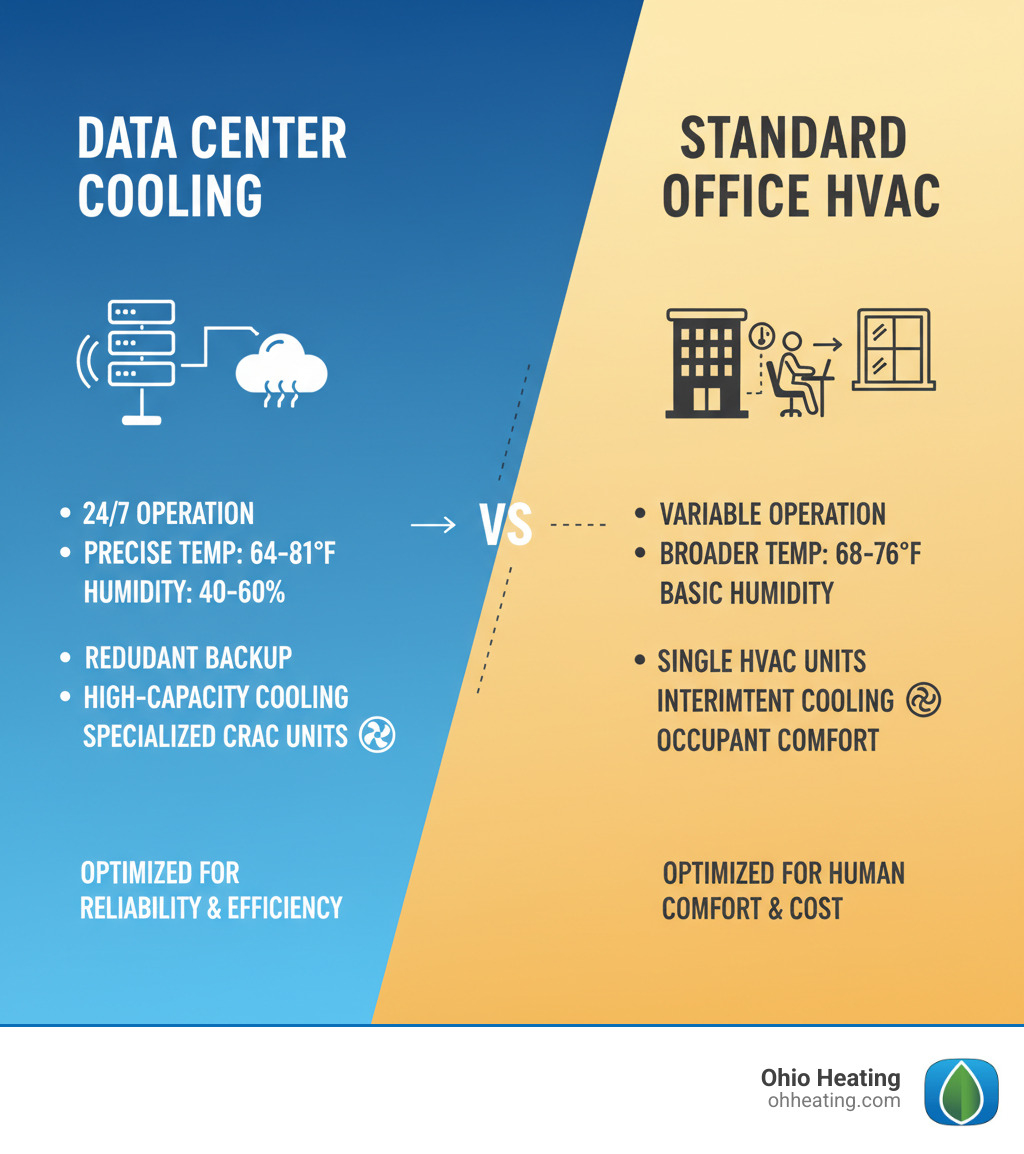

Data centers use about 3% of global electricity, with nearly 40% dedicated to cooling. Unlike standard office AC, data center HVAC handles constant, intense heat loads where failure means lost data and business interruptions costing millions per hour.

Your data center’s HVAC is life support for your servers. It requires disciplined, scheduled maintenance, just like critical hospital equipment. A well-maintained system prevents catastrophic failures, extends equipment lifespan, cuts energy costs by up to 30%, and preserves your warranty.

Planned maintenance costs 25% less than emergency repairs, and a structured program can reduce unplanned outages by up to 66%, according to IEEE standards.

The Critical Role of HVAC in Data Center Operations

Data centers operate 24/7, with thousands of servers generating enough heat to cause rapid overheating without proper cooling. This makes data center HVAC maintenance mission-critical. Without it, you risk equipment failures, corrupted data, and downtime that can cost millions per hour.

Cooling accounts for nearly 40% of a data center’s energy consumption, a massive footprint that directly impacts your Power Usage Effectiveness (PUE). A lower PUE signifies higher efficiency, leading to reduced operational costs and a smaller environmental impact.

Server components are sensitive to temperature swings. Pushing them too hot causes throttling or shutdowns, while excessive drift risks permanent hardware damage.

Why Optimal Temperature and Humidity are Non-Negotiable

Maintaining precise environmental conditions is essential for IT equipment.

Temperature control is the top priority. ASHRAE recommends keeping data centers between 64-81°F, though most operators aim for the narrower 68-77°F range. Exceeding these boundaries accelerates hardware degradation and invites performance issues.

Humidity is just as critical. Too much moisture creates condensation on circuit boards, leading to short circuits, while too little builds up static electricity that can zap components. ASHRAE recommends a relative humidity of 40-60%.

High humidity also accelerates corrosion, while low humidity increases the risk of electrostatic discharge (ESD). Both can silently damage sensitive electronics. Finally, dust and airborne particles can clog cooling systems and trap heat. Precision cooling systems continuously monitor and adjust temperature, humidity, and air quality to maintain the exact conditions required.

Key Components of a Data Center Cooling System

Data center cooling uses industrial-grade, precision systems designed for 24/7 operation. At Ohio Heating, we’ve specialized in these systems throughout Columbus and Central Ohio since 1999.

The workhorses of data center cooling are Computer Room Air Conditioners (CRAC) and Computer Room Air Handlers (CRAH). Both maintain precise conditions, but CRACs are self-contained refrigeration units, while CRAHs use chilled water from external chillers.

Chillers are large-scale refrigeration systems that cool water, which is then circulated through CRAH units to absorb heat. Cooling towers, usually located outside, dissipate the heat collected by the chiller water into the atmosphere, completing the cooling cycle.

Smart air distribution systems, often using raised floors to create an underfloor plenum, deliver cold air through perforated tiles directly to server racks. This setup, combined with hot aisle/cold aisle containment, boosts efficiency by preventing warm and cool air from mixing.

This specialized equipment demands expertise. Our industrial air conditioning heating services provide the technical know-how to keep your operation running smoothly.

A Proactive Approach: The Core of Data Center HVAC Maintenance

Preventive maintenance costs a fraction of emergency repairs. This logic is even more critical for a data center’s cooling system, where the stakes are much higher.

Data center HVAC maintenance protects your entire operation, forming the foundation of continuity, asset longevity, and financial stability. A structured program transforms a facility’s reliability and bottom line. Planned maintenance costs 25% less than unscheduled repairs, and a comprehensive program can reduce unplanned outages by up to 66%, according to IEEE. When downtime costs millions per hour, this is business-critical.

Regular maintenance also keeps equipment at peak efficiency, extending its lifespan by up to 48%. This reduces energy use and ensures your infrastructure won’t fail unexpectedly. To understand more about why this proactive approach matters so much, read our guide on the importance of regular HVAC maintenance for homes and businesses.

Benefits of a Preventive Maintenance Schedule

A preventive maintenance schedule delivers several key benefits:

- Reduced Downtime: Regular inspections and tuning make unexpected breakdowns rare, protecting revenue and customer satisfaction.

- Significant Cost Savings: Beyond costing 25% less than reactive repairs, preventive care avoids premium charges for emergency service and parts. It can also cut energy bills by up to 30%.

- Extended Equipment Lifespan: Consistent care maximizes your return on investment by helping HVAC systems exceed their projected lifespan, deferring major capital expenses.

- Improved Reliability: A well-maintained system provides stable temperature and humidity, allowing IT equipment to operate in ideal conditions with fewer hardware failures.

- Warranty Protection: Most manufacturers require proof of annual maintenance to honor warranty claims, a detail that can save you from shouldering unexpected repair costs.

These benefits explain why we consider preventive maintenance an essential investment. Our comprehensive commercial HVAC services are designed to meet the demanding needs of data centers throughout the Columbus area.

Best Practices for Your Data Center HVAC Maintenance Program

A thorough data center HVAC maintenance program methodically addresses every component to protect your operation.

- Regular inspections: Methodical examinations for leaks, unusual noises, vibrations, and wear on units, piping, and electrical connections to catch small issues early.

- Filter cleaning and replacement: Inspect filters monthly and replace every 1-3 months. Dirty filters restrict airflow, forcing the system to work harder and cool less effectively.

- Coil cleaning: Evaporator and condenser coils accumulate dirt that acts as insulation. Regular cleaning maintains heat exchange and prevents major efficiency losses.

- Lubrication of moving parts: Proper lubrication of fan motors and bearings reduces friction, heat, and wear, extending component life.

- Refrigerant level checks: Ensures full cooling capacity. Low levels force compressors to overwork, so technicians should find and repair leaks before recharging.

- System control monitoring: Regularly check and calibrate thermostats, sensors, and control systems to ensure they read conditions accurately and respond correctly.

- Condensate drain flushing: Prevents clogs from algae and debris that can cause water overflow and equipment damage.

- Electrical connection checks: Inspect connections for tightness and corrosion to prevent resistance, heat buildup, and power interruptions.

These practices form the backbone of reliable data center cooling. For additional strategies, check out our 10 easy commercial HVAC maintenance strategies.

How Regular Upkeep Boosts Energy Efficiency

In a data center where cooling is nearly 40% of the electrical load, efficiency is paramount. Poorly maintained components strain to perform, driving up utility bills and worsening your Power Usage Effectiveness (PUE) score.

According to the EPA, even a tiny layer of dirt on an evaporator coil can reduce efficiency. A “moderately dirty” coil can increase electricity use by over 30%. We’ve seen facilities save thousands annually just by implementing regular coil cleaning.

Tasks like filter changes, coil cleaning, and lubrication ensure the system operates without unnecessary strain, directly cutting energy consumption and improving your PUE. Retrofitting with energy-efficient components can yield further savings. Ohio businesses may even qualify for rebates, making upgrades more affordable. For more ideas, explore our guide on how to boost commercial AC efficiency with smart energy solutions.

The bottom line? Regular upkeep is a proven strategy for controlling one of your largest operational expenses while supporting sustainability goals.

Overcoming Challenges and Ensuring System Reliability

Data centers operate 24/7, generating relentless heat from high-density server racks. Your HVAC system must constantly remove this heat while maintaining precise environmental conditions. The heat loads are intense and unforgiving, far exceeding those in a typical office. As your business adds more racks, cooling capacity must scale accordingly, all without the luxury of a “slow season” for maintenance.

Common Challenges and the Consequences of Neglect

The primary challenge is managing the intense, concentrated heat from high-density racks, which requires effective, localized cooling strategies. Other challenges include planning for scalable cooling infrastructure and ensuring absolute reliability for 24/7 operations.

When data center HVAC maintenance is neglected, the consequences are severe and immediate:

- Equipment Failure: Overheating causes components to degrade rapidly and fail completely.

- Data Loss: Extreme conditions lead to processing errors, file corruption, and data loss.

- Unplanned Outages: A major HVAC failure can halt your entire operation, with downtime costs reaching millions per hour.

- Financial Waste: Neglected systems consume more energy, and emergency repairs are far more expensive than scheduled maintenance.

- Voided Warranties: Many manufacturers require proof of maintenance to honor warranties.

For more insights into what can go wrong, check out our article on common issues causing commercial HVAC system failures.

The Importance of Airflow Management and Redundancy

Efficiently delivering cold air to servers and removing hot exhaust is critical. The hot aisle/cold aisle containment configuration is the industry standard. It arranges racks to separate cold air intake from hot air exhaust, preventing them from mixing and maximizing cooling efficiency. Blanking panels are used to fill empty rack spaces, preventing hot air from recirculating into the cold aisle and further improving efficiency.

Redundancy provides essential backup. N+1 redundancy means having one more cooling unit than required, so if one unit fails or needs maintenance, the system’s capacity remains sufficient. For mission-critical operations, 2N redundancy provides two complete, independent cooling systems, ensuring continuous operation even if one entire system fails. You can learn more about these configurations through resources on N+1 redundancy explained. Modern in-row cooling units, combined with containment, offer an even more resilient and efficient solution.

Navigating Industry Standards and Regulations

Data center HVAC maintenance must meet industry standards for performance, efficiency, and environmental responsibility. The ANSI/ASHRAE Standard 90.4 provides comprehensive energy efficiency requirements for data centers, covering everything from cooling strategies to ventilation.

Though voluntary until adopted by local law, these standards are the benchmark for high-performing, energy-efficient operations that protect equipment and minimize costs. The standard allows for flexibility and encourages heat recovery measures, where waste heat is repurposed—a practice that aligns with growing environmental regulations in Central Ohio.

Compliance involves metrics like the Annualized Mechanical Load Component (MLC), refrigerant specifications, and noise restrictions, which evolve with technology. At Ohio Heating, our maintenance practices are built around these benchmarks. Since 1999, we’ve helped Columbus businesses meet these requirements while ensuring operational reliability. You can explore the full standard details through ASHRAE Standard 90.4.

The Future of Data Center Cooling and Maintenance

The data center landscape is evolving rapidly, driven by the growth of AI and machine learning. At Ohio Heating, we help Columbus businesses steer these changes. The future of data center HVAC maintenance is shifting from reactive fixes to intelligent, proactive systems that are more efficient and sustainable.

Leveraging Real-Time Monitoring and Data Analytics

The industry is moving toward Condition-Based Maintenance (CBM), a transformative approach. Modern smart sensors and IoT integration capture thousands of real-time data points from your HVAC system, including temperature, humidity, and vibration patterns.

The real power comes from AI-driven predictive models and machine learning algorithms that analyze this data. These systems learn your equipment’s normal operating patterns and can detect subtle deviations that signal a potential future failure, often weeks in advance. Instead of an unexpected failure, the system alerts you to early signs of wear, allowing you to schedule maintenance conveniently and avoid an emergency. This is the power of predictive analytics.

These systems also continuously optimize operations, detect subtle anomalies, and help pinpoint the root cause of issues for more effective repairs. The result is a reduction in unplanned outages by up to 66% and energy cost savings of up to 30%—benefits being realized in data centers today.

Emerging Trends and Technologies in Cooling

As high-density racks generate more heat, traditional air cooling is reaching its limits, paving the way for innovative solutions.

Liquid cooling is becoming mainstream because fluids transfer heat more effectively than air. Immersion cooling submerges servers in non-conductive fluid, while direct-to-chip cooling delivers coolant via cold plates directly to hot components like CPUs.

Free cooling is a simple yet powerful innovation. When outdoor temperatures are low enough, these systems use naturally cool air or water to supplement or replace mechanical chilling, saving significant energy. For example, a data center in Norway uses icy fjord water for cooling, slashing its energy needs by a third.

Sustainability is also driving waste heat repurposing. Instead of being vented, the heat generated by servers can be used to warm nearby buildings, heat greenhouses, or even power other cooling systems. It’s a win-win that lowers energy bills and provides a useful resource to the community.

These technologies are becoming operational realities. The future of data center cooling is about managing heat more intelligently, cleanly, and efficiently.

Conclusion

Your data center’s HVAC system is the guardian of your entire operation. Data center HVAC maintenance is not an expense but essential protection for your most valuable assets. A proactive maintenance schedule transforms operations by extending equipment life, cutting energy costs, and drastically reducing unplanned outages. These benefits translate to real savings, uptime, and peace of mind.

Fundamentals like filter changes, coil cleaning, and proper airflow management are the building blocks of reliability. Combining these basics with emerging technologies like predictive analytics and liquid cooling doesn’t just maintain your data center—it future-proofs it.

Since 1999, Ohio Heating has helped businesses in Columbus and Central Ohio protect their critical infrastructure. We understand that because your data center never sleeps, its cooling system can’t afford to either. The choice is simple: pay for regular maintenance now, or pay much more later for emergency repairs and catastrophic business interruptions.

Your cooling system deserves expert care. Let’s ensure your data center remains cool, efficient, and operational for years to come.

Partner with experts for your commercial HVAC maintenance services