Ice Machine Fix: 5 Quick, Easy Fixes

Why Your Ice Machine Matters More Than You Think

An ice machine fix starts with understanding common problems and their simple solutions. Whether your ice maker has stopped, is leaking, or making strange noises, many issues can be resolved with basic troubleshooting before you call a professional.

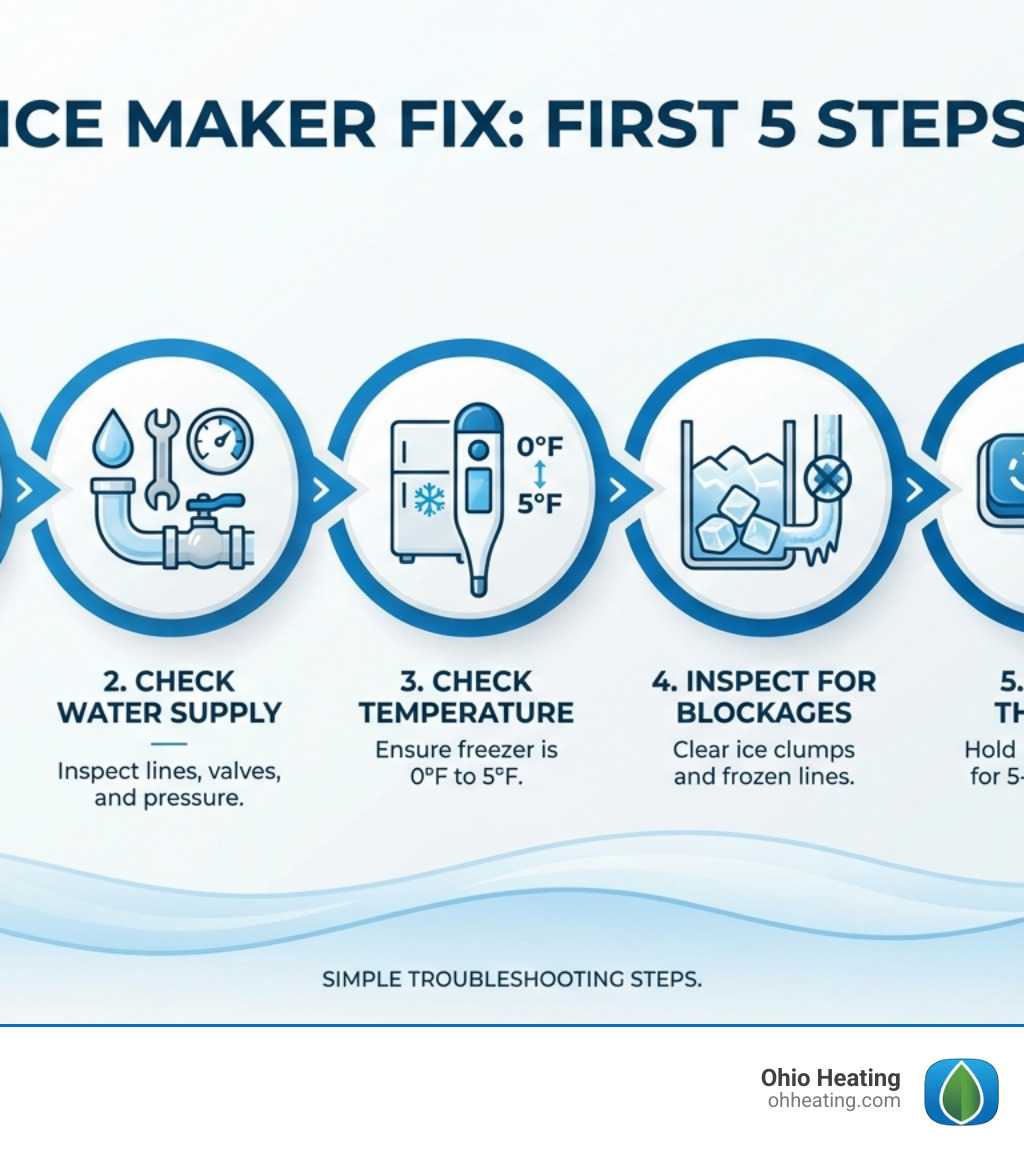

Quick Ice Machine Fix Checklist:

- Check the power – Verify the unit is plugged in and the circuit breaker hasn’t tripped.

- Inspect the water supply – Look for kinked lines, closed valves, or clogged filters.

- Verify temperature settings – The freezer should be at 0°F to 5°F for proper ice production.

- Look for blockages – Check for ice clumps in the bin or frozen water lines.

- Reset the unit – Press and hold the reset button for 5-10 seconds.

When an ice maker stalls, you need fixes you can trust. Most problems stem from common issues like clogged water filters, incorrect temperature settings, or power disruptions, meaning you don’t always need an immediate service call.

For property managers and business owners, a broken ice machine means unhappy tenants or lost revenue. The good news is that many issues can be fixed in minutes with basic troubleshooting, saving you significant money on repair bills. Knowing when to handle an ice machine fix yourself versus when to call a professional is key.

I’m Jill Frattini, a Service Coordinator at Ohio Heating in Columbus, OH. I’ve spent years coordinating commercial refrigeration and ice machine fix projects, and I’ve seen how quick troubleshooting can prevent costly downtime and extend equipment life.

First Steps: Basic Troubleshooting for Any Ice Maker

Before you panic over a lack of ice, let’s walk through some basic troubleshooting. These initial checks often lead to a quick ice machine fix that saves you time and money.

Basic Checks for a Quick Ice Machine Fix

What looks like a major malfunction is often a simple oversight. I’ve cancelled countless service calls by walking people through these checks over the phone.

First, check the control arm position. This sensor arm tells the ice maker to stop when the bin is full. Ensure it’s in the down position and moves freely. A loose or broken arm can send the wrong signal.

Next, look for the on/off switch, which can be accidentally switched off. It’s usually a toggle or push button on the unit itself.

Most ice makers also have a reset button, typically small and red. Press and hold it for 5-10 seconds to perform a soft reset, which can clear minor system glitches.

Don’t forget to check your circuit breaker and make sure the unit is plugged in—a surprisingly common issue.

If you’ve just installed a new unit, give it 24 hours to stabilize its temperature before ice production begins. It may take another 24 to 48 hours to fill the ice bucket completely.

For more insights, check out our article on common ice machine problems.

Checking the Water Supply and Filter

Water supply interruptions stop ice production. Let’s ensure everything is flowing smoothly.

Start with a water line inspection. The small tube running to your unit can develop kinks or blockages. Gently straighten any kinks and check for leaks. Older installations may have a saddle valve that can clog or fail over time; ensure it’s fully open.

Your water filter is crucial for clean, fresh-tasting ice, especially in Columbus where water quality varies. A clogged filter causes slow ice production, small or hollow cubes, or a complete stop. Bad-tasting ice is another telltale sign.

Our golden rule: replace your water filter every six months. Set a reminder, as this simple step prevents countless headaches. You may need to change it more often with hard water or nearby construction. Mineral buildup from poor water quality can restrict flow and confuse sensors, impacting ice production and taste, as noted in scientific research on water quality challenges.

Verifying Freezer Temperature Settings

The correct temperature is critical for an ice machine fix. Your ice maker needs specific conditions to work properly.

The ideal freezer temperature is between 0°F and 5°F. Check your freezer’s dial or digital display and adjust if needed.

If your freezer runs too warm (above 5°F), you’ll see slow production or no ice at all. Many ice makers shut off automatically if the temperature is too high.

Conversely, a freezer that’s too cold (below -10°F) also causes problems. It can lead to hollow ice cubes because the outside freezes too fast, tricking the thermostat into ejecting them before they’re solid.

Adjust your freezer thermostat to 0°F and allow 24 hours for it to stabilize. During hot Ohio summers, you might temporarily turn the temperature down to -2°F to help ice set faster, but keep your main refrigerator compartment between 33°F and 40°F for food safety and efficiency.

Your Step-by-Step Guide to an Ice Machine Fix

Now that we’ve covered the basics, let’s dive into symptom-based solutions for your household or standalone ice maker.

Problem: The Ice Maker Isn’t Making Ice (or Makes Too Little)

This is the most frustrating issue. Here are common causes:

- Frozen Water Supply Tube: A frozen water supply tube is a common culprit, especially if your freezer is too cold. This blocks water from reaching the ice maker.

- Thawing a Frozen Line: To thaw it, turn off the fridge and use a hairdryer on a low setting to gently warm the tube. Never use sharp objects. Afterward, turn the fridge back on and set the freezer to 0°F. For more details, see How to Defrost an Ice Maker.

- Faulty Water Inlet Valve: If the water line is clear but no water enters the ice maker, the electrically controlled inlet valve may be defective. This usually requires professional replacement.

- Low Water Pressure: Ice makers need at least 20 psi of water pressure. If it’s too low, the ice mold won’t fill properly, resulting in small or no cubes. You may need a plumber to check your home’s water pressure.

- Malfunctioning Motor Signs: Unusual noises like humming or grinding can indicate a failing motor, which drives the ejector arms. A failing motor will stop ice production and often requires a professional repair.

Problem: Leaks, Bad Taste, or Poor Ice Quality

These issues detract from the ice experience even if production hasn’t stopped.

- Leaking Causes: A leaking ice maker can damage your flooring. Check for an unlevel unit, a clogged or cracked drain line, or a misaligned fill valve that’s overshooting the ice mold.

- Odd Taste Causes: Bad-tasting ice is a common complaint. The cause is often an expired water filter (change every six months), old ice that has absorbed freezer odors, or poorly wrapped food in the freezer.

- Small or Hollow Cubes: This usually points to a water flow or temperature issue. A clogged filter, kinked line, or low water pressure (under 20 psi) can reduce water flow. An incorrect temperature (below -10°F) can cause cubes to freeze too quickly on the outside, creating hollow centers. Adjust your freezer to 0°F.

- Cloudy Ice: This is caused by trapped air and minerals. Using filtered water and ensuring a slow freezing cycle can improve clarity.

Problem: The Ice Maker is Frozen or Dispensing Issues

When the unit is blocked or won’t dispense, it’s time for action.

- Ice Blockage in Bin or Chute: If ice is produced but won’t dispense, check for an ice clump blocking the bin or chute. Gently break up clumps or remove the bin to defrost it. A hairdryer on low can speed this up.

- Frozen Auger Motor: In dispenser models, the auger moves ice to the dispenser. If the motor freezes, it won’t turn. This often requires defrosting the entire compartment.

- Faulty Door Switch: This switch controls the light and ice dispenser. If it’s faulty, the ice maker may think the door is open and won’t dispense. If the light doesn’t turn on when you open the door, the switch may be the problem.

- Ice Maker Making Too Much Ice: An ice maker that won’t stop causes overflow. This is often due to a mispositioned bin or a faulty control arm that doesn’t sense when the bin is full.

For more on specific repair challenges, consult our article on identifying ice machine repair challenges in Columbus.

Special Considerations for Commercial Ice Machines

For businesses in Central Ohio, an ice machine fix is about keeping operations running and customers happy. Commercial ice machines are more complex than residential units, and a breakdown can mean lost revenue and frustrated patrons in a restaurant, hotel, or healthcare facility.

Common Issues and Maintenance for Commercial Units

Commercial ice machines are workhorses that require extra care. Here are common issues:

- Low ice output is a frequent complaint, often caused by high ambient temperatures (above 70°F), clogged lines, dirty filters, or a dusty condenser.

- A machine that won’t turn on might be unplugged, have a tripped breaker, or have its selector switch on ‘OFF’ or ‘CLEAN’. More serious issues include wiring failures or a bad control board.

- Ice that won’t release often points to dirty or misaligned sensors that fail to start the harvest cycle.

- Poor ice quality (hollow, small, or bad-tasting cubes) usually traces back to water quality issues or clogged filters.

- Water leaks can stem from plumbing issues, clogged drains, or an unlevel machine.

- An ice maker that won’t shut off typically has a malfunctioning sensor or control arm that fails to detect a full bin.

How often should you schedule professional maintenance? Schedule service every 3-6 months. High-volume businesses need it every 3 months, while lower-volume ones can go 6 months. Dusty environments or areas with hard water may require more frequent service. Regular maintenance includes deep cleaning, sanitizing, and inspecting components. This can extend the life of a machine by 2 to 3 years. With proper care, most commercial units last 7 to 10 years.

For more on commercial service, see our guide on ice machine install and service in Columbus.

Advanced Troubleshooting for a Complete Ice Machine Fix

When basic fixes fail, it’s time for advanced diagnostics.

Commercial machines come in several types (full-cube, half-cube, nugget, flake), each with unique quirks but similar operating principles.

Business owners often ask: Should I repair or replace? Most problems are repairable, but consider these factors:

- Age: If your machine is under 7 years old, repairs usually make sense. For machines over 10, replacement might be more economical.

- Cost: A good rule of thumb is if the repair cost exceeds 50% of the replacement price, a new, more efficient machine is often a better investment. New units cost $2,000 to $10,000+.

Certain issues always require a professional:

- Compressor problems are a major repair. As the heart of the system, a failure (indicated by grinding noises or no cooling) can cost $3,000+ to fix.

- Control board failures cause erratic behavior or a complete shutdown. These are expensive and require expert diagnosis.

- Sealed system leaks involving refrigerant are complex and require an EPA-certified technician to repair safely and legally.

At Ohio Heating, we’ve handled commercial ice machine repairs since 1999. We understand downtime costs you money. Learn more about our commercial ice machine sales and repairs.

Frequently Asked Questions about Ice Machine Repair

Over the years, we’ve fielded countless calls about ice makers. Here are answers to the most common questions.

Why is my ice maker not working after changing the filter?

It’s frustrating when an ice maker stops working after a filter change, but it’s a common issue. First, ensure the filter is the correct model and is installed correctly, as an improper fit can block water flow.

Air often gets trapped in the water line after a filter change. To fix this, purge the air by dispensing a few gallons of water from the refrigerator’s water dispenser. If the problem persists, the issue may be unrelated to the filter, and it’s time to check other potential causes.

How do I reset my ice maker?

A simple reset can often solve what seems like a major failure. Most ice makers have a reset button, usually a small red or white button on the control panel or under the unit. Press and hold it for 5-10 seconds.

If there’s no reset button, perform a “hard reset” by unplugging the unit for 5 minutes and then plugging it back in. This clears the memory and can resolve minor electronic glitches. After resetting, allow the ice maker a few hours to cool down and begin a new cycle.

How long does a new ice maker take to start working?

Patience is key with a new ice maker. After installation, a unit needs at least 24 hours to reach its optimal operating temperature before it starts making ice.

Once production begins, it can take up to 48 hours to completely fill the ice bucket. This is normal. It’s also a good idea to discard the first one or two batches of ice, as they may contain residue from the new water lines. If you still have no ice after 48 hours, revisit the basic troubleshooting steps or give us a call.

Conclusion: When to Call the Professionals

We’ve covered many simple DIY ice machine fix solutions, from replacing a filter to clearing a blockage. These fixes can often get your ice maker running again, empowering you to solve minor issues and save money.

However, some problems require professional expertise. If basic troubleshooting fails, it’s time to call a pro. Issues like faulty compressors, electrical problems, or refrigerant leaks are dangerous to handle yourself and could void your warranty or cause more damage. Don’t risk your safety or more expensive repairs.

This is especially true for commercial ice machines, where downtime directly impacts your bottom line. A restaurant or hotel without ice faces a business crisis where lost revenue can quickly exceed the cost of a professional repair.

At Ohio Heating, we’ve been keeping Columbus comfortable since 1999. Our team has serviced over 100,000 units with a high first-time fix rate. We offer same-day, 7-day-a-week repairs for all major brands with no extra charges for evening or weekend calls, because we know emergencies don’t keep business hours.

Right now, we’re offering $55 OFF each complete ice machine fix.

Don’t let a broken ice machine put your comfort or business on hold. Our expert technicians have the knowledge and tools to diagnose and repair your system correctly the first time.

Get professional commercial ice machine sales and repairs from the team that’s kept Central Ohio cool for over two decades.