Sweltering summer temperatures put a special strain on commercial refrigeration systems, and the last thing a Columbus business owner wants is a spoiled inventory or a costly emergency repair. At Ohio Refrigeration, we understand that proactive maintenance is the key to uninterrupted cooling performance. In this post, we’ll walk you through a summer-time preparation checklist tailored for refrigeration in Columbus, covering condenser-coil maintenance, refrigerant inspections, airflow optimization, and more. By following these management tips, you’ll mitigate heat-related failures and ensure your coolers, freezers, and walk-ins stay chill all season long.

Understanding Summer’s Impact on Commercial Refrigeration

Summer’s high ambient temperatures and humidity can:

Overload Condenser Coils: Hotter air reduces heat transfer efficiency, forcing compressors to work harder.

Accelerate Refrigerant Loss: Thermal expansion and contraction exacerbate tiny leaks.

Compromise Airflow: Blocked vents or dirty filters cause uneven cooling and pressure imbalances.

By anticipating these challenges, you can schedule targeted inspections and services before tropical heatwaves wreak havoc on your business.

Summer-Ready Checklist: Essential Tasks for Peak Performance

Before the mercury climbs above 80°F, tackle these critical tasks:

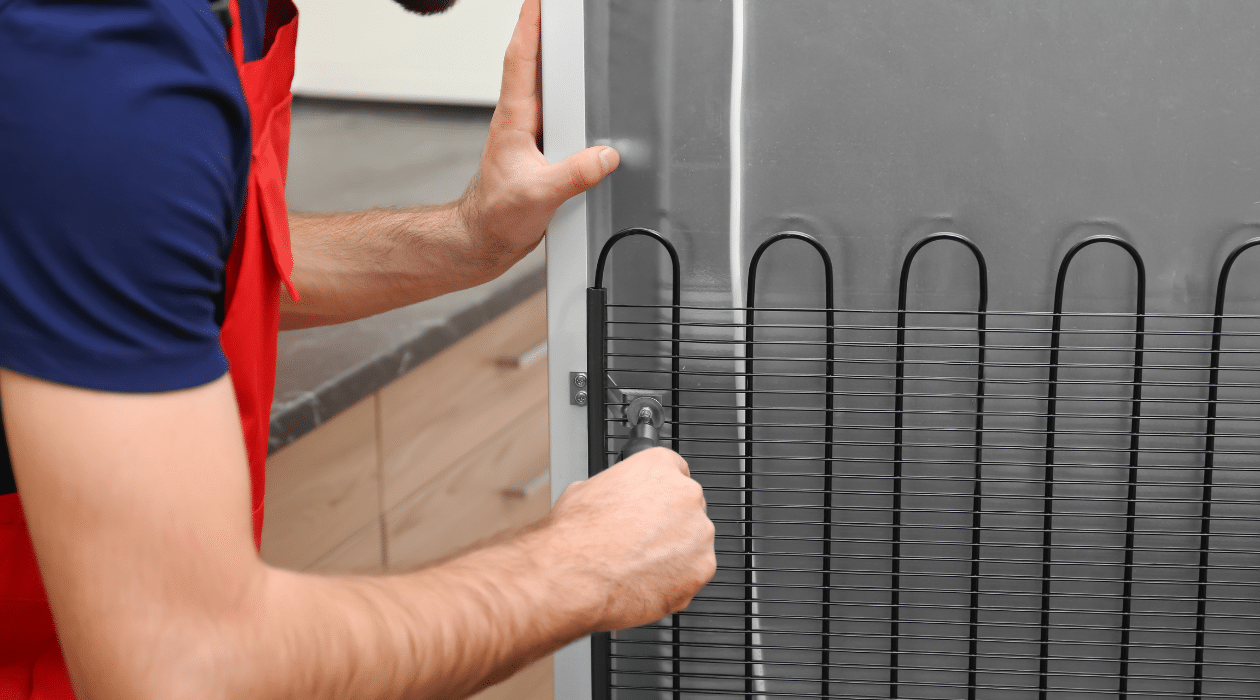

Condenser-Coil Cleaning & Inspection

Remove debris: Leaves, grass clippings, and dust can accumulate between fins, use a soft-bristle brush or low-pressure washer.

Straighten fins: Bent fins restrict airflow; fin combs restore optimal spacing.

Coil condition: Inspect for corrosion or oil stains indicating refrigerant leaks.

Refrigerant Level Verification

System pressure check: Measure suction and discharge pressures against manufacturer specs.

Leak detection: Use electronic leak detectors or dye tests to pinpoint loss.

Top-off or recharge: If levels are low, top off with the correct refrigerant, never substitute blends.

Airflow Optimization

Evaporator fan motors: Lubricate bearings and verify RPM to maintain consistent cold air distribution.

Vent clearance: Ensure at least 12 inches of clearance around condensers and condenser fans.

Filter replacement: Swap dirty filters for high-MERV units to block dust while preserving airflow.

Electrical & Control Systems Review

Thermostat calibration: Confirm setpoints with an independent thermometer.

Wiring integrity: Inspect for signs of melting insulation or rodent damage.

Safety switches: Test high-pressure and low-pressure cutouts to prevent compressor overheat.

Drain Line & Pan Maintenance

Unclog condensate drains: Use enzyme cleaners to dissolve biofilm and prevent overflows.

Pan inspection: Check for rust or cracks; replace pans that could leak onto floors.

Condenser-Coil Maintenance: The First Defense Against Heat Stress

The condenser coil’s job is to dump heat absorbed inside your cooler. In summer, a clean coil is your frontline defense:

Biweekly Cleaning: During heavy pollen or construction seasons, increase cleaning frequency to every two weeks.

Protective Coatings: Consider a hydrophobic coil coating that repels water and dirt buildup.

Professional Coil Service: Schedule an annual deep-clean and inspection with a maintenance plan to catch hidden issues.

A well-maintained coil can improve energy efficiency by up to 30%, reducing both wear and utility bills.

Refrigerant Inspections: Ensuring Optimal Charge & System Health

Proper refrigerant charge is vital for temperature control:

Pressure-Temperature Chart Matching: Verify measured pressures correspond to the rated refrigerant’s saturation temperature for the current ambient conditions.

Superheat & Subcooling Tests: Calculate superheat and subcooling to assess charge accuracy, imbalances indicate over- or undercharge.

Leak Repair Protocols: Pinpoint leaks in brazed joints or service valves, repair, and re-evacuate the system to restore vacuum before adding refrigerant.

If you suspect refrigerant contamination or require retrofits, consult Ohio Refrigeration for expert guidance.

Airflow & Ventilation: The Backbone of Consistent Cooling

Even small airflow disruptions can cause significant temperature swings:

Fan Blade Cleaning: Dust-laden fans lose up to 20% of their airflow capacity, clean blades monthly.

Evaporator Coil Frost Checks: Frost buildup signals poor airflow, defrost manually and address the underlying cause.

Return-Air Grille Clearing: Keep internal return vents free from boxes, displays, or debris to maintain even suction.

Optimizing airflow not only preserves food safety but extends equipment lifespan by reducing compressor cycling.

Electrical & Controls: Fine-Tuning Your Refrigeration Brain

Your refrigeration controls are the “brain” of the system, mis-calibrated sensors or faulty wiring can lead to expensive misfires:

Thermostat Accuracy: Use a shaded reference thermometer to cross-check digital readouts.

Defrost Cycle Verification: Ensure defrost timers and heating elements engage properly; irregular defrosts lead to ice buildup.

Compressor Load Tests: Monitor amperage draw; elevated current can indicate mechanical or electrical strain.

For comprehensive control system audits, explore our restaurant refrigeration services tailored to high-demand commercial kitchens.

Drainage Solutions: Preventing Water Damage & Mold Growth

A clogged condensate drain is more than a nuisance, it can flood equipment rooms and foster mold:

Enzyme-Based Cleaners: Monthly treatments keep drain lines clear without harmful chemicals.

Physical Cleaning: Use a wet/dry vacuum to suck out stubborn blockages.

Overflow Protection: Install float switches that shut down the compressor and trigger an alarm if water levels rise.

Maintaining a clear drain line protects both your equipment and your facility’s infrastructure.

Scheduling & Documentation: Proactive Summer Time Preparation

Prevention is the ultimate cost saver. Implement:

Quarterly Inspections: Comprehensive system checks before, during, and after peak season.

Digital Maintenance Logs: Record all tasks, findings, and repairs in a centralized platform for easy reference and compliance.

Automated Reminders: Set calendar alerts for filter changes, coil cleanings, and electrical tests.

A documented maintenance program underscores your commitment to safety and reliability, essential for health inspections and insurance compliance.

Conclusion: Stay Cool with Expert Refrigeration in Columbus

As the sun blazes and business heats up, don’t let your commercial refrigeration systems break a sweat. By following this summer-ready checklist, including condenser-coil maintenance, refrigerant inspections, airflow optimization, and robust documentation, you’ll prevent heat-related failures and protect both product quality and profits.

Reach out to us: Have questions or need personalized service? Call 614-863-6666 or visit our website. We’re proudly serving Columbus businesses with expert refrigeration solutions, keeping you cool under pressure, all summer long.